NTSB Reveal Lax Maintenance Standards in Honolulu Tour Helicopter Accident (Bell 206B3 N80918)

On 18 February 2016 a Bell 206B3, N80918, operated by Genesis Helicopters, impacted the water of Pearl Harbour, Honolulu, HI during a scenic tour following a transmission component failure due to poor maintenance.

Genesis Helicopters Bell 206B3 N80918 Survivable Water Impact (SWI) in Pearl Harbour, Honolulu (Credit: Shawn Winrich) White Star Marks USS Missouri as a Fixed Reference Point. Time from First Photo to Fourth (Impact) c 3s

One passenger, a 16 year old boy, died in hospital 4 days later, after this Survivable Water Impact (SWI). The pilot and two other passengers suffered serious injuries and a fourth passenger escaped with minor injuries. The US National Transportation Safety Board (NTSB) safety investigation highlights some shocking maintenance standards.

The Accident Flight

During the local scenic flight the pilot explained that:

…as he began the approach to Ford Island [in the centre of Pearl Harbour], he noticed a vibration throughout the cabin of the helicopter that seemed “different.” He decided to return directly to HNL [Honolulu Airport]; however, the vibration stopped, and he made a left turn so the passengers could see the USS Arizona Memorial.

Shortly thereafter, the vibration returned, and the pilot called the air traffic control tower at HNL to advise that the flight would be returning to the airport.

The controller instructed the pilot to hold for other inbound helicopters, which implies no emergency was declared at that time.

…at this point, the vibration developed into a grinding sensation. Then the main rotor low rpm warning light illuminated, and engine rpm began to rise; the point where the engine and rotor RPM needles were no longer matched on the power turbine gauge. The pilot then lowered the collective, reduced the throttle and realized the engine and main rotor were no longer connected as he began to look for a place to land.

His first chosen landing site, the grassy area next to Pearl Harbor Memorial visitor’s centre, became impossible as the USS Arizona Memorial ferry had started to disembark there.

…the pilot turned the helicopter slightly left to land [i.e. ditch] in the water as close to shore as possible… He stated that when the helicopter was about 20 ft above the water, it felt like the rotor stalled, the helicopter lost lift, and it “fell out of the sky.” The helicopter descended rapidly into the water about 20 ft from the shoreline.

A review of video captured by a witness revealed that the…helicopter’s forward airspeed appeared to decrease, the nose pitched up, and the helicopter began to rotate to the left in a slightly nose-up attitude then descended rapidly into the water. At the time of impact, the helicopter appeared to be in a slightly nose-high, left bank attitude.

The 16 year old boy was trapped in the helicopter. A number of ‘good samaritans’ near the memorial, including a police officer and a navy diver, made 5-6 attempts to free the boy from the submerging wreckage. When they did release him, he was taken to shore and treated by visiting medical personnel, although he died in hospital on 22 February 2016. The official cause of death was anoxic encephalopathy, or brain injury, due to drowning.

Genesis Helicopters and their FAA Oversight

Genesis Helicopters, founded in 1999, operated a single helicopter and employed 4 people:

- the owner (who was a licensed pilot and A&P mechanic)

- a mechanic’s assistant (who was unlicensed)

- a pilot (who was flying the helicopter that day)

- a receptionist

They had a Letter of Authorization (LOA) from the Federal Aviation Administration (FAA) to conduct air tours within 25 statute miles of the departure airport under Part 91.147, a rather basic requirement with few obligations.

The owner told the NTSB that the FAA visited “kind of a lot” but when asked when the last visit was he said it had “been a while”. A team of three (a Principal Operations Inspector [POI], Principal Avionics Inspector and Principal Maintenance Inspector [PMI]) should be assigned to LOA holders, it appears that only a PMI was assigned and he had only completed On The Job training 2 months before.

The last ramp or records inspection had been 3 January 2013 (over 3 years earlier and on an earlier helicopter operated by the company), although the PMI had left a phone message on the morning of the accident to arrange an inspection. Actually, national FAA policy would only require ramp or records inspections of only a 10% annual sample, of LOA holders and an operations inspection is not required!

The owner was asked by the NTSB why he had not sought a Part 135 Air Taxi Operating Certificate:

He stated that it was due to the amount of time required to obtain a 135 certificate. He said it would take 1.5 years to get the certificate and he did not have the resources to dedicate to the project, which was another reason for hiring the accident pilot; he would have time to focus on the business side of the operation to complete the 135 process.

The owner said the company’s air tour clientèle came mostly from hotels and a well known travel booking website.

When asked why there were emergency floats installed on the helicopter, the owner stated “it was due to weight”.

They weighed about 150 pounds, which was the equivalent to one person. He said the helicopter did have a set of floats when they acquired it, but immediately took them off since they were not required.

‘Not required’ likely refers to federal regulations not requiring floats on aircraft operating close to shore.

Maintenance History

The owner and mechanic’s assistant related that maintenance had been conducted to replace an engine-to-transmission drive shaft seal in late January 2016. The NTSB explain that:

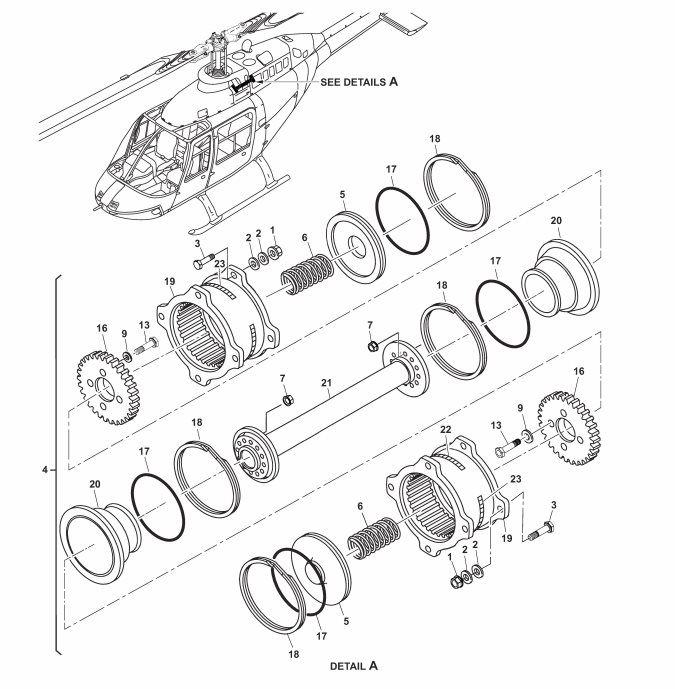

The drive shaft (as installed) is comprised of two identical couplings, which are located on either end of the shaft. The internal components consist of two flanges positioned on the ends of the tubular, hollow drive shaft.

The assembly requires a retainer ring and packing seal to be positioned against the flange. A drive shaft coupling seal is situated against the packing seal, impeding grease from egressing the coupling assembly.

The drive shaft contains a gear sprocket [items 19] affixed to the shaft flange via 4 bolts (bolt heads positioned on the inside of the coupling). The donut-shaped gear has a hollow area in the middle that aligns with the hollow tube situated between the couplings; a slight lip surrounds the hollow area. The outer coupling gear surrounds the drive gear where it is splined, and torque is transmitted. Inside the coupling, the assembly is equipped with a shaft centering spring. The spring (item 6 [above]) is positioned between the lip and the end cap of the coupling (grease retainer plate). A retainer ring and packing seal rest against the back plate.

The BHT [Bell] maintenance manual recommends that, before reassembly, the engine-to-transmission drive shaft couplings be hand-packed with lubricant (C-015 grease) over the top of the internal spline teeth to a depth of 0.2-0.3 inch.

When records could not be found for this task the owner said that they “must not have gotten put in the logbooks”.

So maintenance was going unrecorded. In fact the NTSB say:

No entries referencing a current annual inspection [or] current 100-hour inspection…were located within the airframe and engine logbooks.

Furthermore:

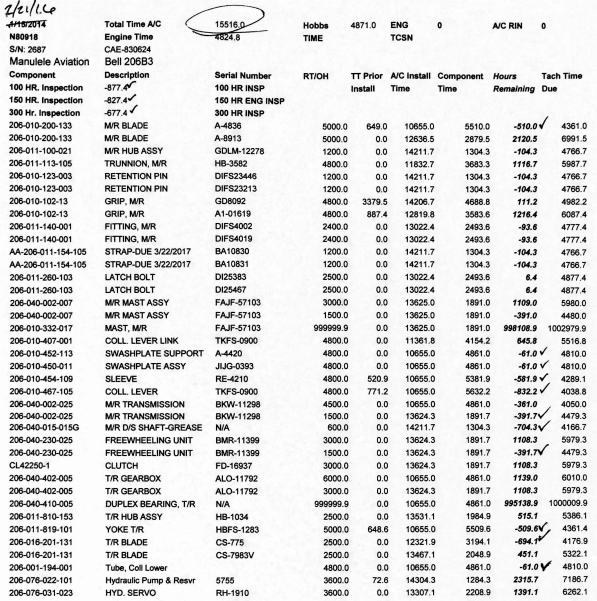

The owner provided a component status sheet on February 21, 2016. There were several items that indicated negative time remaining before an inspection was due.

Several of these items were annotated with check marks; the owner indicated that these inspections had been completed, but the sheet had not yet been updated.

The NTSB asked about the negative-time items that were not ticked. Some related to the engine and the owner stated a loan engine was installed so they could be worked upon. However, when asked about the other items which were seemingly overdue, the owner accepted that the rotor Tension-Torsion (TT) straps were overdue.

When asked if he knew they were due at the time of the accident, he stated that he knew they were coming due, but did not know that the helicopter had flown that extensively, and did not know they were due until he printed the status sheet for the investigation.

The long list of other components were not discussed in detail. It was also stated by the owner that (as stated in the NTSB’s transcript) “there would not have been anything like a countdown to an inspection”.

So there was no active control of scheduled maintenance and due tasks, with maintenance overdue.

In relation to the conduct of the maintenance:

The owner stated that he witnessed the initial build-up of the shaft, then left the hangar for about an hour to an hour and a half. When he returned, the mechanics assistant had already begun installing the shaft into the helicopter. The owner recalled asking specific questions about the bolts going into the shaft, to include if there was friction on the nuts, to which the assistant responded that there was.

The mechanic’s assistant recalled that:

Although the owner of the company was not present the entire time, he was checking the process and quizzed him on the parts and the type of grease used, and he was present to verify that the proper amount of grease was used before installing the shaft.

So supervision was suspect. Furthermore the mechanic’s assistant said:

…he had re-used the same nuts, bolts, and washers to reassemble and reinstalled the short shaft.

The Bell Maintenance Manual required the use of new nuts.

So inappropriate parts were fitted.

No independent inspection was reported, though one is not required on a small aircraft in the US.

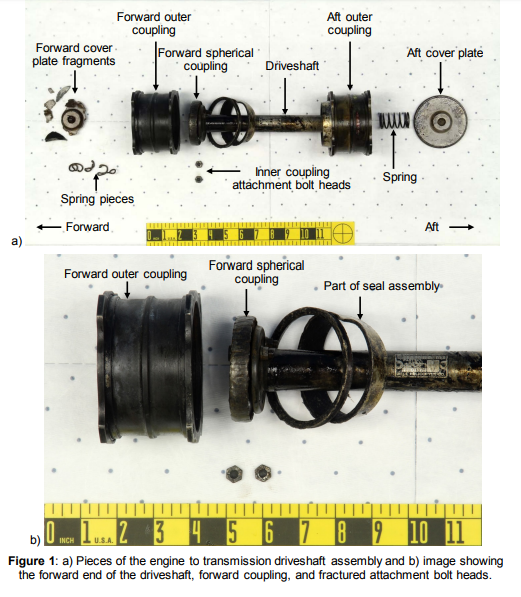

When the wreckage was examined…

…the forward end of the engine-to-transmission drive shaft was not rotating properly. The four bolts holding the outer coupling were loose with no torque stripe present. Additionally, two of the four bolts holding the inner coupling were missing. Two sheared bolt heads were located; the remainder of the bolts and nuts were not recovered.

When removed, the forward retaining ring was still in place; however, only the center of the retainer plate was found, and the centering spring was fractured/deformed. The outer coupling was missing the three temperature plates. No visible evidence of any grease on the inner/outer coupling was observed. The gear teeth on the inner gear coupling were worn away. The aft inner/outer couplings were still attached and had minor damage.

The engine-to-transmission drive shaft was sent to the NTSB Materials Laboratory for further examination.

Investigators say:

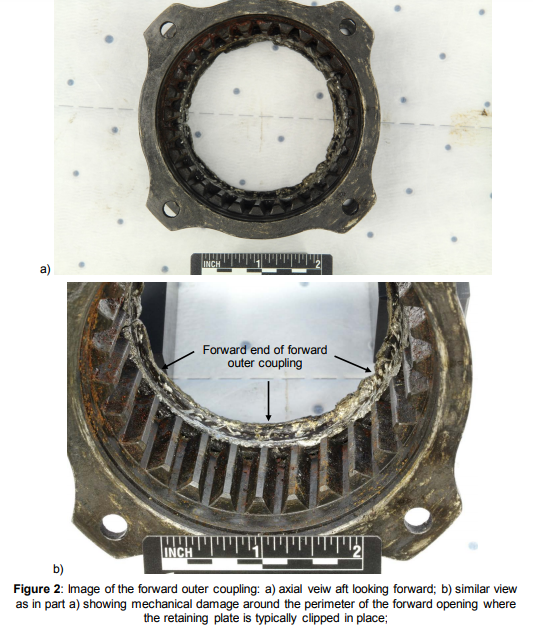

The forward outer coupling had a dark tint consistent with exposure to elevated temperatures and the temp plates (present on the aft outer coupling) were missing. As shown in figure 2b [above], the forward end of the forward outer coupling exhibited mechanical damage around the perimeter of the forward opening.

Neither the forward spherical coupling nor the forward outer coupling exhibited indications of residual grease lubrication. By comparison, the aft outer coupling and spherical coupling were covered by a lubricant that was brown/black in color and viscous. The aft coupling did not exhibit any notable wear features.

NTSB Analysis

Interviews with the pilot, the owner of the company, and a non-mechanic rated maintenance assistant indicated that maintenance had recently been conducted on the engine-to-transmission drive shaft, even though this was not recorded in the helicopter’s maintenance records. In addition, the owner, who was a rated mechanic, was not present the entire time throughout the removal, inspection, and subsequent reinstallation of the engine-to-transmission drive shaft.

It is likely that, when this maintenance was conducted, grease was not applied to the forward coupling as specified in the manufacturer’s maintenance manual. Further review of maintenance records revealed no entries pertaining to a current annual inspection or 100-hour inspection. Additionally, a component inspection sheet provided by the operator revealed that several required component inspections were overdue and had not been completed at the time of the accident.

Although the FAA was conducting oversight in accordance with their guidance, increased inspections may have uncovered the inadequate maintenance and documentation, which in turn, may have prevented the accident.

NTSB Probable Cause

The in-flight failure of the engine-to-transmission drive shaft due to improper maintenance, which resulted in low main rotor rpm and a subsequent hard landing to water.

Safety Resources

We have looked at the poor culture of an air tour operator, weak FAA supervision and poor selection by ticket sellers (in that case cruise ship operators) here: All Aboard CFIT: Alaskan Sightseeing Fatal Flight

Maintenance error featured in another air tour helicopter accident: Fatal $16 Million Maintenance Errors

Critical maintenance tasks were discussed in this article: EC130B4 Accident: Incorrect TRDS Bearing Installation

This article discussed errors greasing helicopter rotors: For Rotors Grease is the Word!

This R44 accident also featured misassembly: Insecure Pitch Link Fatal R44 Accident

Also:

- James Reason’s 12 Principles of Error Management

- How To Develop Your Organisation’s Safety Culture

- Maintenance Human Factors: The Next Generation

- Critical Maintenance Tasks: EASA Part-M & -145 Change

UPDATE 7 April 2018: Investigators Criticise Cargo Carrier’s Culture & FAA Regulation After Fatal Somatogravic LOC-I. A Shorts 360 N380MQ, operated by SkyWay Enterprises as a Part 135 flight on contract to FedEx crashed in the Caribbean after the crew likely suffered a Somatogravic Illusion raising the flaps on a dark night in 2014. The lack of an FAA SMS regulation for Part 135, the operator’s poor safety culture and implications for the wider industry culture stand out in a thoughtful accident report.

UPDATE 24 June 2018: B1900D Emergency Landing: Maintenance Standards & Practices The TSB report posses many questions on the management and oversight of aircraft maintenance, competency and maintenance standards & practices. We look at opportunities for forward-thinking MROs to improve their maintenance standards and practices.

UPDATE 25 August 2018: Crossed Cables: Colgan Air B1900D N240CJ Maintenance Error On 26 August 2003 a B1900D crashed on take off after errors during flying control maintenance. We look at the maintenance human factor safety lessons from this and another B1900 accident that year.

UPDATE 8 September 2018: Torched Tennessee Tour Trip (B206L N16760) An ungreased fuel pump spline failed, the aircraft crashed and suffered a fatal post crash fire.

UPDATE 13 October 2018: Low Viz Helicopter Accident, Alaska

UPDATE 20 May 2019: Regulatory oversight of New Zealand helicopter operators was challenged after a 2015 accident.

UPDATE 7 February 2020: S-61N Damaged During Take Off When Swashplate Seized Due to Corrosion

UPDATE 9 May 2020: Ungreased Japanese AS332L Tail Rotor Fatally Failed

UPDATE 13 September 2020: Hawaiian Air Tour EC130T2 Hard Landing after Power Loss (Part 1)

UPDATE 18 October 2020: Hawaiian Air Tour EC130T2 Hard Landing after Power Loss (Part 2 – Survivability)

UPDATE 17 January 2021: Grand Canyon Air Tour Tragic Tailwind Landing Accident

UPDATE 3 July 2021: EC130 Door Loss Damaged Main Rotor Blades

UPDATE 9 July 2022: R44 Ditched After Loss of TGB & TR: Improper Maintenance

Aerossurance is pleased to sponsor the 9th European Society of Air Safety Investigators (ESASI) Regional Seminar in Riga, Latvia 23 and 24 May 2018.

Recent Comments