Ex-Military Agricultural OH-58C Crash After MRB Fatigue Crack (N139RD)

On 1 November 2016 Bell OH-58C N139RD, on a Rotorcraft Development Corporation Restricted Type Certificate, operated by Helicopter Applicators, was substantially damaged during initial climb at Cameron, North Carolina. The pilot, who sustained minor injuries, was conducting a Part 137 agricultural ‘aerial application flight’, to spray herbicide, in the restricted-category ex-military helicopter.

In their safety investigation report, released in November 2019, the US National Transportation Safety Board (NTSB) say:

After loading the helicopter with herbicide, the pilot departed from the staging area; however, during the initial climb, as the helicopter was about 50 ft above the ground, the outboard portion of one of the two main rotor blades separated.

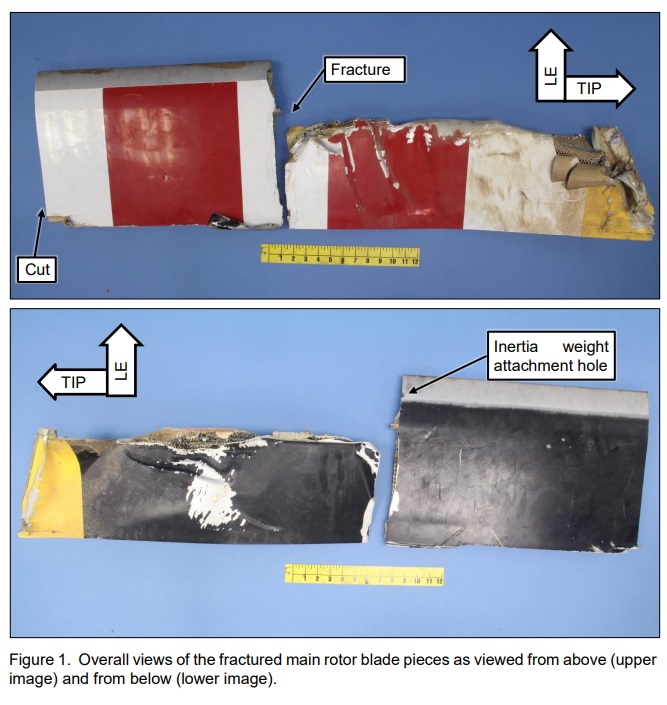

Helicopter Applicators Bell / Rotorcraft Development OH-58C N139RD White Main Rotor Blade Inboard of Tip Cap Failure (Credit: NTSB)

The main rotor blades then struck the tailboom, and the helicopter entered an uncontrolled descent to the ground.

Safety Investigation

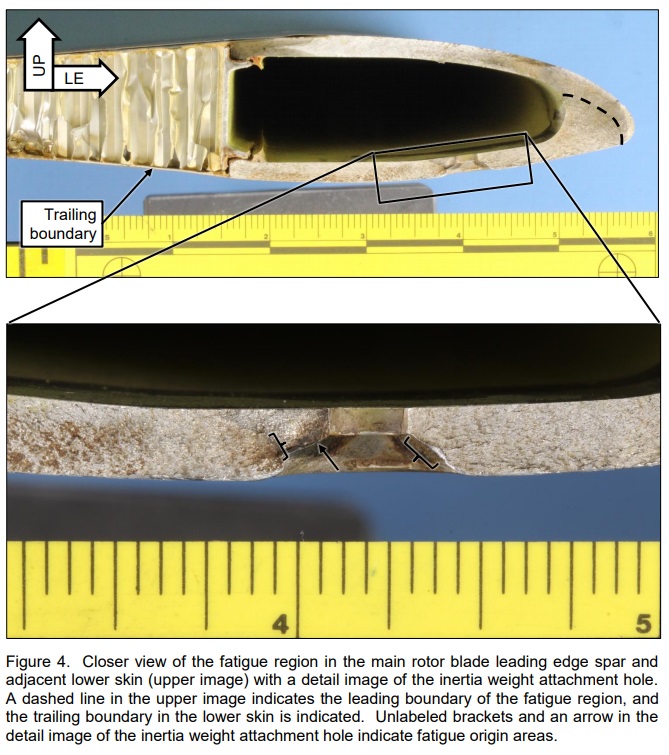

Metallurgical examination of the fractured [white] main rotor blade revealed a crack with fatigue features emanating from multiple origins in the area of the inertia weight attachment hole.

Furthermore:

According to FAA airworthiness records, the accident helicopter, serial No. 71-20396 was manufactured in 1971. It was originally owned and operated by the U.S. Army, and issued an FAA special airworthiness certificate in the restricted category for the purpose of agriculture and pest control on May 4, 1999. According to the FAA type certificate database, the accident helicopter serial No. and registration No. were listed in the approved serial number list under type certificate data sheet No. R00006DE. The original holder of this type certificate was Garlick Helicopters Inc., and the type certificate was transferred to Rotorcraft Development Corporation on February 2, 2009.

Bell had published…

…Military Alert Bulletin (MAB) USA-OH-58-87-1, revision B, originally dated August 12, 1987, and revised April 12, 2007. The purpose of the revised MAB was to notify military operators of model OH-58A, B, C and 206B-1 model helicopters with part numbers 206-011-250-003/113 main rotor blades to conduct initial visual inspections of the blades before returning them to service and subsequently inspect them at intervals of 8 hours or 32 flights, whichever occurred first. The inspection, to be performed with a 10x power scope was focused on the area of the inertia weight screw heads. Paint was to be removed prior to the first inspection, and a clear-coat finish was to be applied to facilitate subsequent inspections.

On April 12, 2007, Bell also issued Operations Safety Notice (OSN) OSN-GEN-07-38, Revision A, to all OH-58 operators referencing the aforementioned MAB and providing a notification of changes incorporated in the revised MAB. Both the MAB and OSN noted that the inspection requirement did not apply to main rotor blades manufactured by Bell Helicopter identified with serial Nos. A-1 and subsequent.

However, this OSN only applied to the aircraft serial numbers that Bell were responsible for. Bell were not responsible for ex-military helicopters where other organisations had successfully applied to the FAA to be the Type Certificate Holder.

Rotorcraft Development was unaware of both the MAB and the OSN prior to the accident. The maintenance program created by Garlick Helicopters had also not specified inspecting the main rotor blade as per the MAB and OSN either.

The NTSB say that:

Performance of the recurrent inspection required by the MAB and the OSN likely would have detected the fatigue cracks on the main rotor blade before its failure during the accident flight.

The Dubious Effectiveness of non-OEM TCH Continued Airworthiness Support

NTSB comment that there is no requirement for multiple-TCH’s to share information. We would however observe that the FAA allowing multiple TCH’s is a fundamentally flawed continued airworthiness arrangement that silos type knowledge and allows non-OEM TCHs to operate without detailed knowledge of the type design.

We’ve previously written: Usage Related Ex-Military Helicopter Accident (UH-1H, N175SF). There we asked: It is an interesting question whether most of these [non-OEM] TCH’s really have the data and competence to manage this design airworthiness matters of ageing ex-military rotorcraft in niche roles.

In October 2019 the FAA issued Information to Operators (InFO) 19011.

On September 28, 2016, the Federal Aviation Administration (FAA) received a Safety Hotline Complaint that identified owners/operators of commercially used OH-58A, A+, and C helicopters using incorrect calculation methods to determine the life-limit of engine parts and components. Although these parts and components should have a life-limit based on hours, not cycles, the complainant specified that the Garlick ICA and the Type Certificate Data Sheet (TCDS) contain limits that exceed FAA approved specific criteria for the OH-58A, A+, and C aircraft.

The InFO acknowledges that this TCDS is now held by Rotorcraft Development but not that Rotorcraft Development closed its doors in December 2016!

The FAA review confirmed the information provided by the complainant. Section II, Airworthiness Limitations Section, of the Garlick ICA references Allison Engine Company publication 5W2 & l OW2 for retirement intervals. The FAA reviewed these documents, identified the life-limit requirements for the 250-C20 & 250-C18 engines, and confirmed that engine components are life-limited by hours and/or cycles.

The ICA document identifies an FAA-accepted formula for computing initial cycles of life-limited engine components not being tracked by cycles. The formula multiplies engine or engine component total time (in hours) by 2.5, which gives the cycle count. The serial number list in the TCDS identifies a total of 47 registration/serial numbers of OH-58A, A+, & C rotorcraft. The safety concern is that this formula, used for military surplus life-limited OH-58 engines and engine components, is being used universally for all military surplus life-limited engines and engine components not previously tracked using the cycle count method.

The formula in the Garlick ICA is specifically for military surplus life-limited OH-58 model engines and engine components listed in the No. RDC-TC03. The formula is not intended to be used on engines and engine components that have not been previously tracked using the cycle count method.

NTSB Probable Cause

An in-flight failure of a main rotor blade due to fatigue cracks.

Contributing to the failure of the main rotor blade was the absence of guidance to the operator to inspect an area of the main rotor blade known to be susceptible to fatigue cracks and the accident helicopter type certificate holder’s lack of information of an existing inspection published by another restricted-category type certificate holder of the same model helicopter.

Safety Resources

We have also written:

- Wasp Stung By Lack of Lubrication An ex-military Westland Wasp HAS1 crashed out of control. The military Maintenance Schedule assumed 200FH pa and an MGB overhaul ever 600FH. This MGB was fitted for 429 hours over 20 years.

- Yuma Hawk Accident: Lessons on Ex-Military Aircraft Operation A US fatal accident with an ex-Korean BAe Hawk, operated by a defence contractor, highlights some of the issues of civil use of ex-military aircraft.

- Usage Related Ex-Military Helicopter Accident (UH-1H, N175SF)

- Ungreased Japanese AS332L Tail Rotor Fatally Failed

- For Rotors Grease is the Word

- Maintenance Misdiagnosis Precursor to EC135T2 Tail Rotor Control Failure

- Misassembled Anti-Torque Pedals Cause EC135 Accident

- EC130B4 Accident: Incorrect TRDS Bearing Installation

- Fatal S-61N Dual Power Loss During Post Maintenance Check Flight

- AAIB Report on the Ditchings of EC225 G-REDW 10 May 2012 & G-CHCN 22 Oct 2012

- EC225 LN-OJF Accident Norway (29 April 2016) Investigation Timeline

- AAR Bell 214ST Accident in Afghanistan in 2012: NTSB Report

- Fatal S-61N Dual Power Loss During Post Maintenance Check Flight

- Loss of AS332L1 LN-OPG off Brønnøysund, Norway, 8 September 1997

- Insecure Pitch Link Fatal R44 Accident

- EC135 Main Rotor Actuator Tie-Bar Failure

- Bell 429 TR Pitch Change Link Bearing Failure

- S-61N Damaged During Take Off When Swashplate Seized Due to Corrosion

- Tail Rotor Pitch Control Loss During Hoisting

- Sikorsky S-92A Loss of Tail Rotor Control Events

- NTSB Reveal Lax Maintenance Standards in Honolulu Tour Helicopter Accident

- Maintenance Issues in Fire-Fighting S-61A Accident

- Freewheel Jerk on an SA330J Puma at Sea: Oil Analysis Opportunity

Recent Comments