A Screw in the Wrong Place…A Loss of Hoist Cable (Honda Airways AW139 JA03FD Breeze-Eastern Hoist)

On 17 February 2024, Leonardo AW139 JA03FD of Honda Airways, operated for the Saitama Disaster Prevention Air Squadron, inadvertently released the hoist cable and test load during a post-maintenance hoist check at Honda Airport, Kawajima.

Saitama Disaster Prevention / Honda Airways Leonardo AW139 JA03FD (Credit: @stone15DJ)

The Japan Transport Safety Board (JTSB) issued their safety investigation report on 25 May 2025.

The Serious Incident Flight

The helicopter’s hoist cable had been replaced and so a post-maintenance check flight was necessary. On board were two pilots, an Air Squadron Officer (ASO – the hoist operator) and a mechanic (‘Mechanic A’, acting as a hoist instructor).

The JTSB explain:

The load test required after cable replacement, confirms each function of hoist operates normally with maximum hoist load, 600lb (about 272 kg). In this case, the cable had been replaced the day before by Mechanic B and C, and it was planned to conduct load test, with 136 kg…and [then] 272 kg….on the hook at the end of the cable.

This would be achieved using two and then four 68 kg weights.

At about 10:17, for the first load test, the helicopter reeled out the cable to the ground at a hovering height of about 50 ft, and ground crew hooked a 136 kg weight.

The helicopter then climbed to hovering altitude of about 340 ft, the Air Squadron Officer began to reel out cable to the maximum length (about 300 ft), which was for Mechanic A to confirm that it would automatically stop at the maximum length.

As the cable reached its maximum extension “the weight fell to the ground along with the cable” near Taxiway E4. There were no injuries or damage.

The helicopter had an electrically operated Breeze-Eastern hoist:

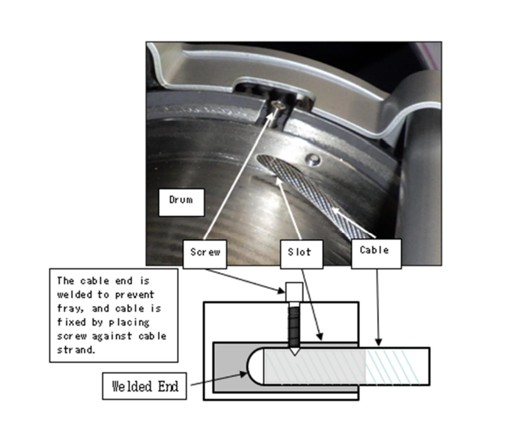

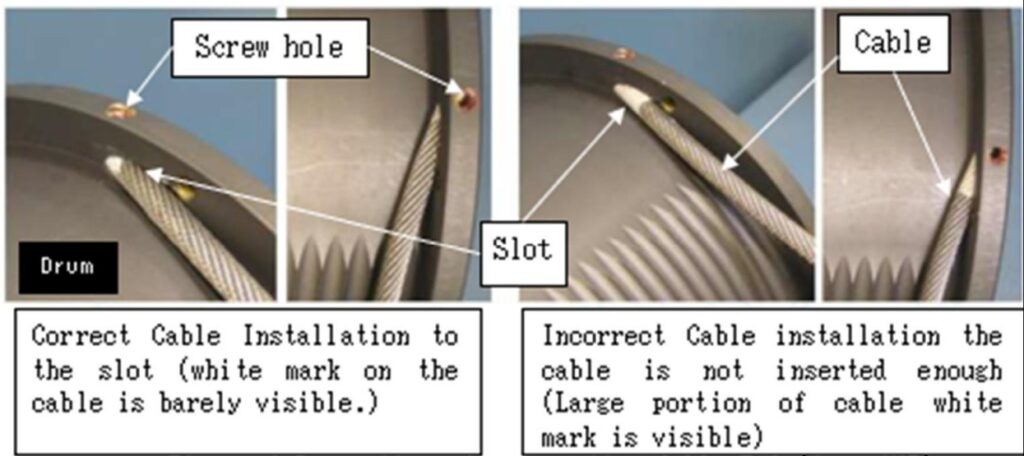

The cable is 307 ft (about 93.5 m) long, has a diameter of 4.75 mm, and is wrapped on an aluminum drum. The cable is inserted in the slot of drum and fixed by tightening the screw against the cable strand.

As the end of the cable is welded to prevent fraying, the screw must contact the cable strand and not the welded end. The hoist is fitted with limit switches which automatically stop the drum when remaining cable gets to 3.5 to 4.5 wraps.

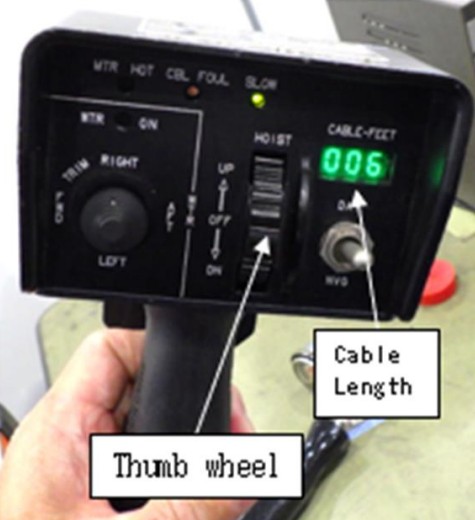

Unacceptable ‘bird caging‘ damage had been found on the previous cable fitted to the hoist so on 15 February 2024 ‘Mechanic B’ (a licenced engineer) began to unwind the old cable using the thumb wheel on the hoist pendant.

Mechanic B stopped unwinding when the full-out limit switch actuated and the drum stopped, confirmed that the number of cable wrap which was 4 remaining on the drum and took a photo with his smartphone. And then, Mechanic B removed the screw which fixed the cable end…to pull out the old cable from the slot on the drum and completed the day.

The AW139 Aircraft Maintenance Manual (AMM) however required the limit switch be overridden and the cable fully paid out. The AMM also discusses this screw, saying:

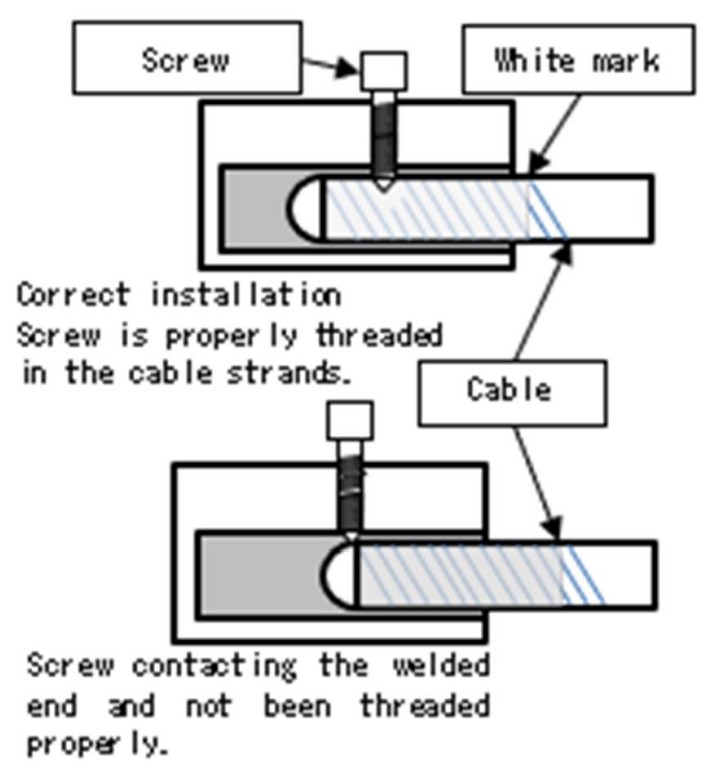

Make sure that the screw engages sufficiently the cable end to safety the cable correctly into the drum shoulder. To do this, you can see only a small part of the cable white mark that goes out of cable housing in the drum shoulder

Carefully obey the given precautions before you install the applicable screw to prevent unwanted loss of cable.

On the next day Mechanic C (also a licenced engineer) started to install the new cable.

Looking at the picture Mechanic B provided, Mechanic C wound four wraps of the new cable on the drum.

Following Mechanic A’s photograph, rather than the AMM “likely reduced workability and made it difficult to fully insert the cable”.

Mechanic C applied anti-seize compound to the new screw and temporarily tightened the screw into the screw hole by hand. In the next step, Mechanic C inserted the end of the new cable into the slot to the end, confirmed that the white marked end was barely visible.

Mechanic C tightened the new screw which was temporarily screwed to the specified value using a torque wrench, pulled the cable to check if it is tight and completed the new cable installation.

Then Mechanic B joined, and was asked to check the cable attachment and both of them performed the operation check required after the cable replacement, checking operation of limit switches and movements.

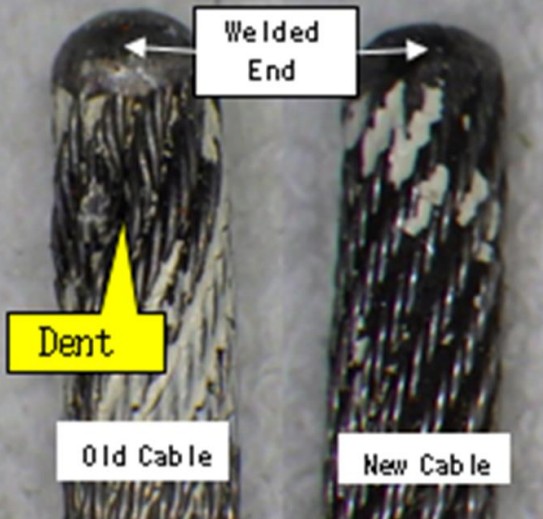

Investigators examined the cable fitted at the time of the accident and the previous cable. The older cable had a distinct conical indent consistent with the securing screw but the cable fitted on the accident had no such indentation.

They examined the screw. That was found to have been screwed six turns. But trials showed that 8 turns were required to achieve the specified torque with a correctly positioned cable.

Investigators concluded that the screw had actually come into contact with the welded end of the cable. They note that the Component Maintenance Manual (CMM) also required a visual check through the screw hole before installing the screw, but Mechanic C was, correctly, using the AMM not the CMM, and was simply judging the amount of white marking visible.

It is probable that the new screw, which was not properly fixed, loosened while the various operational tests and the new cable detached with the load during the load test.

JTSB Probable Cause

The load test was conducted most likely without the cable properly attached to the drum when it was replaced, causing the cable to come loose from the drum when it was fully unwound the cable detached from the drum and fell with the weight.

The reason why the cable was not properly attached to the drum probably because the cable had not been replaced in accordance with specified maintenance procedure.

Safety Actions

The JTSB report that Honda Airways took the following actions:

- This case was introduced within the company, and the mechanics were reminded to follow the maintenance procedures for all work.

- The task card for the cable replacement have been revised in line with the revised AMP, and mechanics was requested to strictly follow the newly added procedure.

- In addition to specified maintenance procedure, original check procedures were added to ensure that the cable is secured firmly

While sharing details of this case study is useful, a reminder to follow procedures isn’t. Added emphasis in the task card is more valuable as is potentially, the unspecified extra check.

Meanwhile Leonardo revised the AMM and…

…added a Caution note to ensure that the cable is inserted correctly by looking through the screw hole when the cable is attached to the drum.

Safety Resources

The European Safety Promotion Network Rotorcraft (ESPN-R) has a helicopter safety discussion group on LinkedIn. You may also find these Aerossurance articles of interest:

- SAR Hoist Cable Snag and Facture, Followed By Release of an Unserviceable Aircraft

- HH-60L Hoist Cable Damage Highlights Need for Cable

- Guarding Against a Hoist Cable Cut

- Fatal Fall From B429 During Helicopter Hoist Training

- TCM’s Fall from SAR AW139 Doorway While Commencing Night Hoist Training

- SAR AW139 Dropped Object: Attachment of New Hook Weight

- Military SAR H225M Caracal Double Hoist Fatality Accident

- Fatal Taiwanese Night SAR Hoist Mission (NASC AS365N3 NA-106)

- SAR Helicopter Loss of Control at Night: ATSB Report

- ‘Procedural Drift’: Lynx CFIT in Afghanistan

- US Fatal Night HEMS Accident: Self-Induced Pressure & Inadequate Oversight

- HEMS Black Hole Accident: “Organisational, Regulatory and Oversight Deficiencies”

- Taiwan NASC UH-60M Night Medevac Helicopter Take Off Accident

- B1900D Emergency Landing: Maintenance Standards & Practices

- ATR 72 Rudder Travel Limitation Unit Incident: Latent Potential for Misassembly Meets Commercial Pressure

- B214ST Tail Rotor Drive Shaft Coupling Misassembly

- SAR AS365N3 Flying Control Disconnect: BFU Investigation

- In-Flight Flying Control Failure: Indonesian Sikorsky S-76C+ PK-FUP

- AAR Bell 214ST Accident in Afghanistan in 2012: NTSB Report

- Misassembled Anti-Torque Pedals Cause EC135 Accident

- EC130B4 Accident: Incorrect TRDS Bearing Installation

- Ungreased Japanese AS332L Tail Rotor Fatally Failed

- R44 Ditched After Loss of TGB & TR: Improper Maintenance

- Missing Cotter Pin Causes Fatal S-61N Accident

- CHC Sikorsky S-92A Seat Slide Surprise(s)

There is also this article that considers hoist cables: Helicopter Hoisting and the Human in the System

You might find these safety / human factors resources of interest:

- James Reason’s 12 Principles of Error Management

- Back to the Future: Error Management

- This 2006 review of the book Resilience Engineering by Hollnagel, Woods and Leveson, presented to the RAeS by Aerossurance’s Andy Evans: Resilience Engineering – A Review and this book review of Dekker’s The Field Guide to Understanding Human Error: The Field Guide to Understanding Human Error – A Review

- Airworthiness Matters: Next Generation Maintenance Human Factors

FSF Maintenance Observation Programme (MOP)

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements:

Aerossurance can provide practice guidance and specialist support to successfully implement a MOP.

Recent Comments