Ungreased Japanese AS332L Tail Rotor Fatally Failed (Toho Air Sevices JA9672)

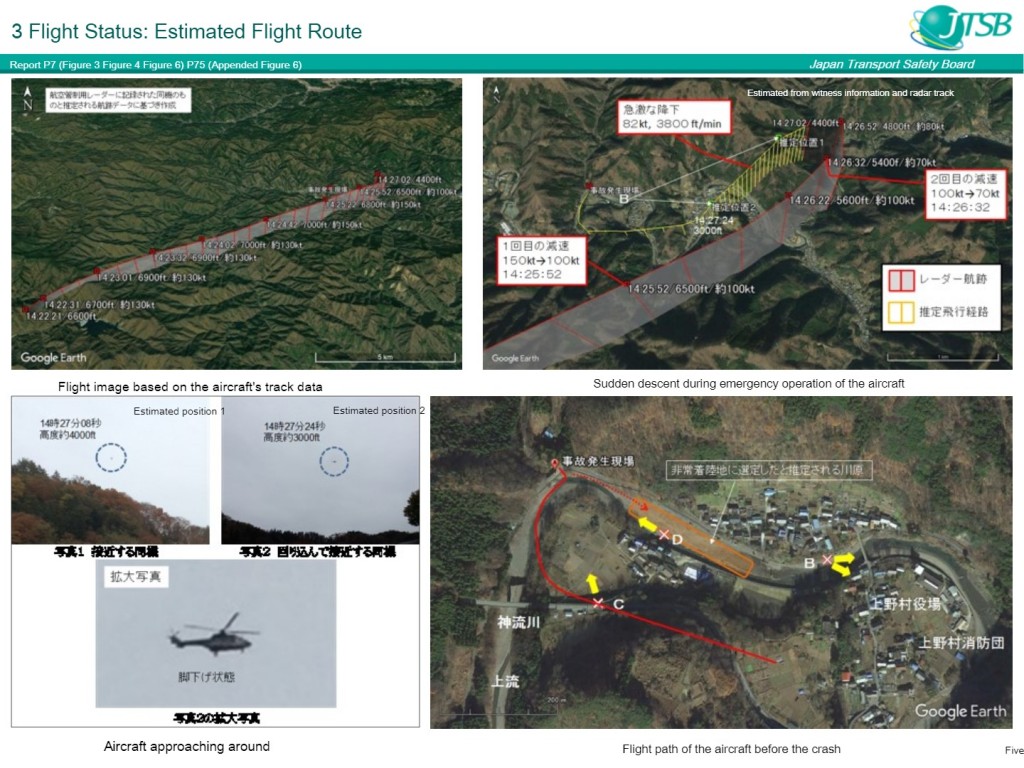

On 8 November 2017, Airbus Helicopters AS332L Super Puma JA9672 of Toho Air Service crashed in Gunma prefecture after the tail rotor separated from the aircraft as the crew prepared to make an emergency landing. There were four people on board, who all died. There was a post crash fire.

The Japan Transport Safety Board (JTSB) concluded in their safety investigation report (published in Japanese on 23 April 2020) that:

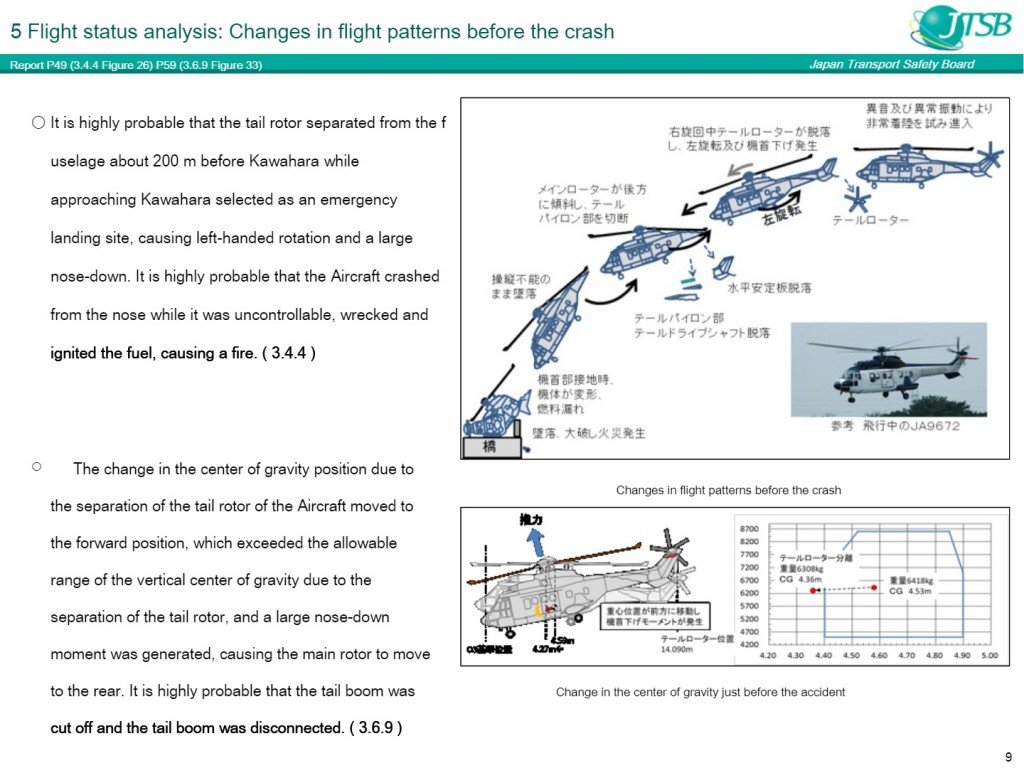

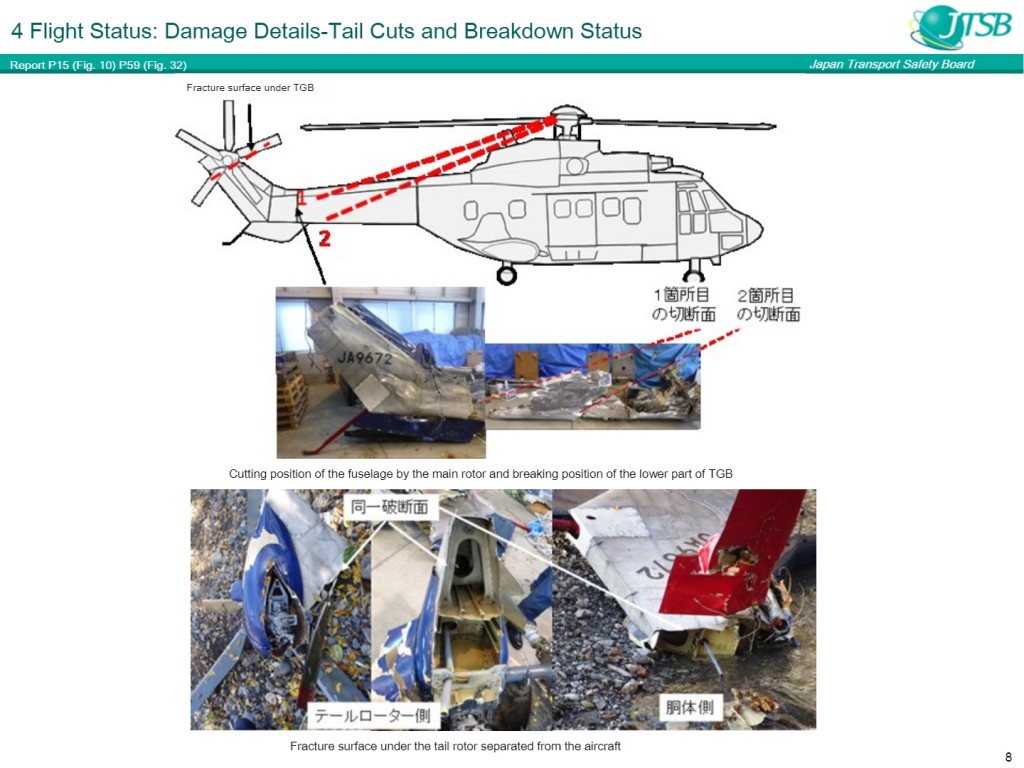

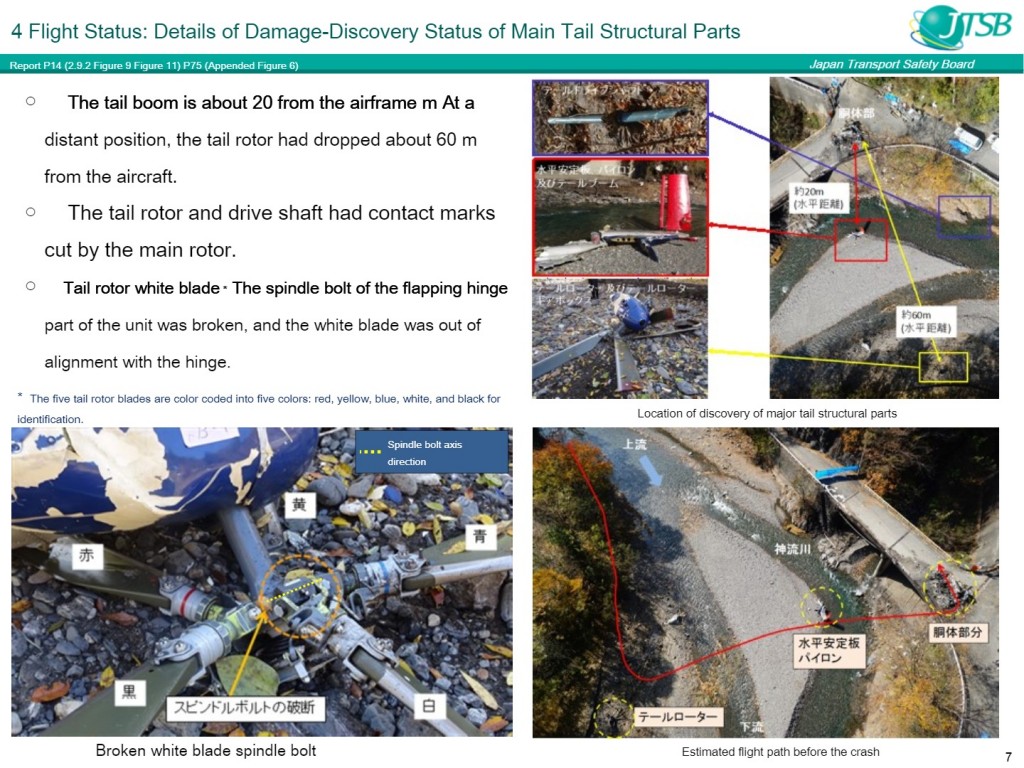

- It is highly probable that the crash occurred because the tail rotor separated from the aircraft when it tried to make an emergency landing due to abnormal vibration that occurred during the flight…

- The tail rotor separated from the fuselage because the spindle bolt of the white tail rotor blade flapping hinge broke and the tail rotor became unbalanced…

- It is presumed that the spindle bolt broke because the bearing of the flapping hinge was damaged [which] was not detected by inspection.

The following JTSB presentation slides that we have translated show the accident sequence:

These graphics illustrate how lucky the 17 occupants of Bond AS332L G-PUMH were in 1995 when a tail rotor flapping hinge retainer had failed due to a fatigue crack emanating from a grease nipple hole while returning from a North Sea offshore installation. G-PUMH was able to make a safe landing at Longside, near Peterhead.

Background

Toho use their AS332Ls for construction projects.

Early in the history of the of the AS332L, the manufacturer had noticed that using Shell Aeroshell 14 grease in tail rotor pitch change hinge bearings had increased the tendency for false brinelling to occur. In 1991 Exxon Mobil MOBILPLEX 47 grease was introduced as an alternative. This was a great success but in February 2008 production of MOBILPLEX 47 was abandoned. Subsequently the manufacturer noticed that on the return to the inferior Shell grease a…

…reduction in the reliability of the tail rotor hub bearing [occured], especially within the helicopter operating range under hot and humid conditions.

Coincidentally, before this accident occurred on 6 December 2016, Aerossurance spoke at a breakout session organised by EASA at their 10th Rotorcraft Symposium in Cologne on rotor and rotor drive system safety. One of the points made in that session was that a crucial contribution that the oil industry can make to helicopter safety is the production of optimised lubricants, even though they may have a small market.

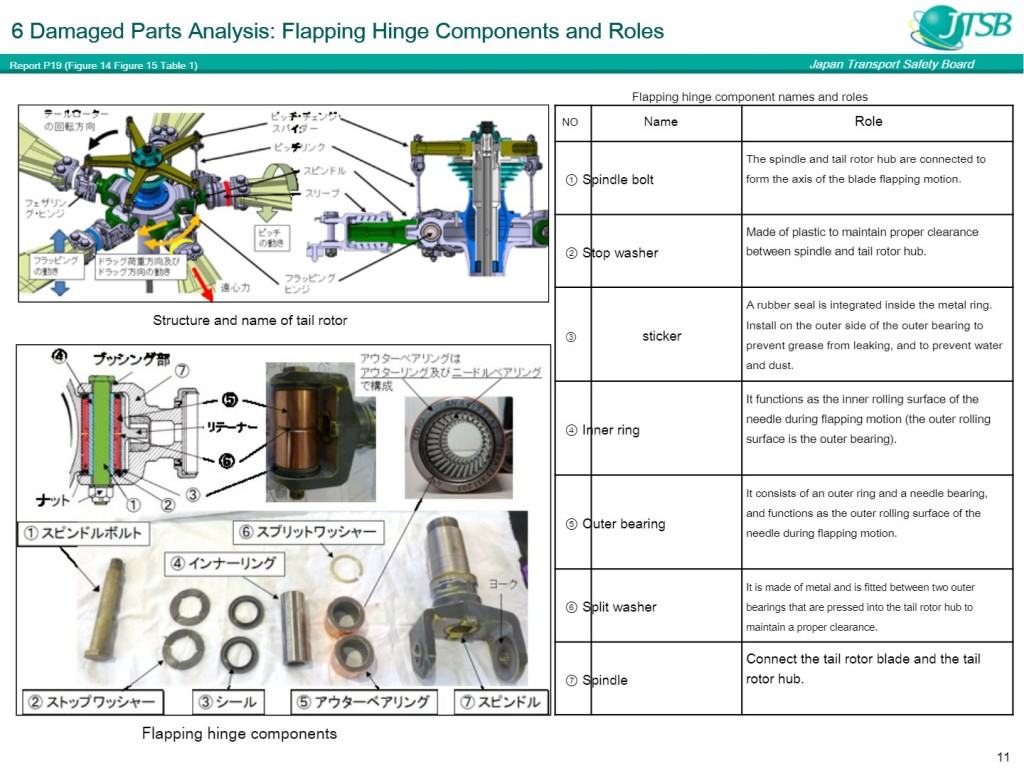

The continued airworthiness of the five AS332L tail rotor flapping hinges were reliant on greasing every 10 flying hours (or daily if parked in hot and humid conditions), as well as 50 and 250 hour inspection. The newer four bladed AS332L2 and EC225 tail rotors feature an improved design.

Structure of Airbus Helicopters AS332L Tail Rotor Hub Flapping Hinge – Note Inner / Outer ‘Rings’ = ‘Races’ (Credit: JTSB)

JTSB could not find evidence of a seal replacement on that blade since June 2014 and postulate the seal had been deteriorating by 2017. As the aircraft was parked outside in high humidity during summer 2017 that would have allowed moisture ingress into the grease. Unfortunately it appears the maintenance personnel were not aware that they should have re-greased the tail rotor due to the humid environment each day either.

Inspections from July 2017 started to show the grease in the white blade’s hub starting to turn increasingly black and by September 2017 “movement of the white blade was not smooth”. JTSB believe these were indications of bearing deterioration. However, no corrective maintenance action was taken initially.

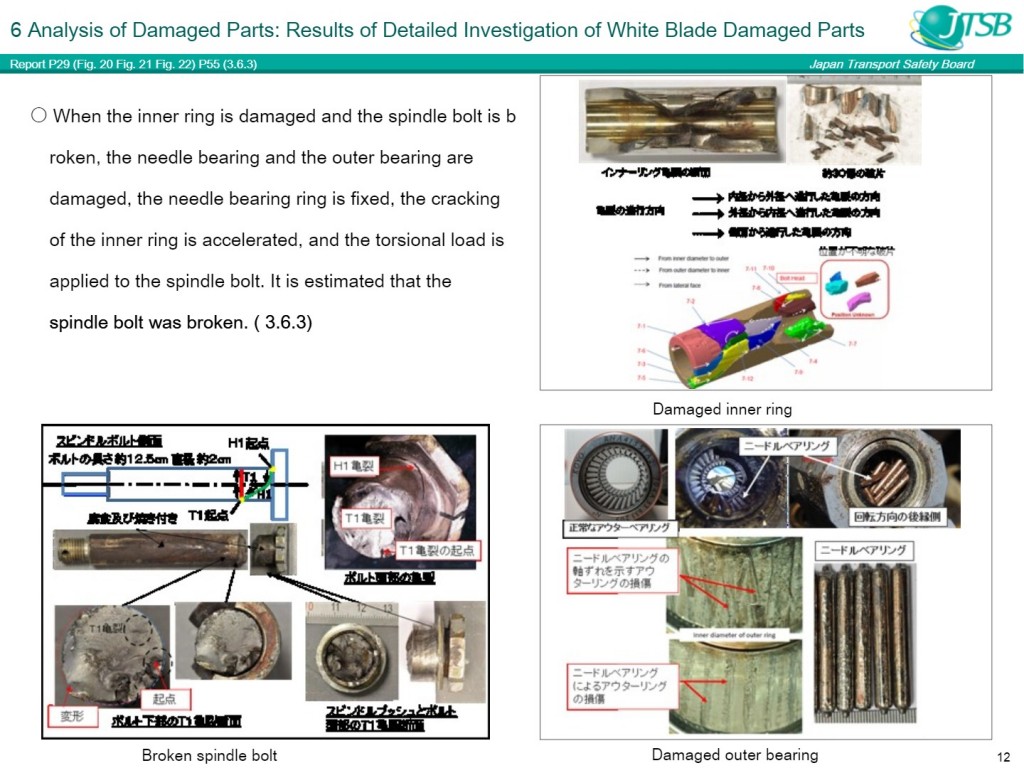

The aircraft was subject to a 250 hour inspection 20-23 September 2017. The white blade’s inner race was found cracked and the inner race and the stop washer were replaced. JTSB note that:

The condition of the outer bearing was not confirmed, and the seal was not replaced.

The seal replacement was a Maintenance Manual requirement. They also postulate that as the new inner race was used to force out the damaged old inner race, that some debris may have been left behind. The level of damage to the inner race should have required notification to Airbus too say JTSB. This was not done.

From around 31 October 2017, low-frequency c 1Hz lateral vibration was felt in the cockpit. The aircraft was not fitted with HUMS and this was misdiagnosed as due to a slight oil leak from the lip seal of the sleeve of a main rotor blade.

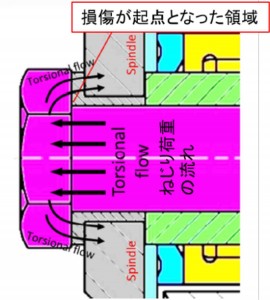

Post-accident laboratory examination concluded that the cracks in the spindle bolt of the aircraft showed a “twisted state” indicating that the spindle bolt was subjected to an “unexpected fatigue load”. They demonstrate in their report this was most likely due to the bearing deterioration.

Loads in Tail Rotor Flapping Hinge Bolt Toho Air Services Airbus Helicopters AS332L JA9672 (Credit: JTSB)

Continued Airworthiness Action

On 21 November 2017, less than two weeks after the accident, Airbus Helicopters EASB No. AS332-64.00.43 was issued which was referenced by EASA Emergency Airworthiness Directive (EAD) No.2017-0232-E. This AD required…

…a one-time inspection of flapping hinges of the tail rotor blades and, depending on findings, corrective action(s) [and] reporting of the detected findings and sending any cracked components to AH to support the investigation.

In February 2018 this was expanded to include the similar SA330J Puma.

On 15 November 2018, Airbus Helicopters EASB No. AS332-05.01.10 was issued, covered by EASA Airworthiness Directive (AD) No.2018-0248, which required component replacements.

The latest EASA AD is No.2020-0086.

UPDATE 6 August 2021: This accident will be subject of a JTSB presentation at the ISASI 2021 virtual seminar.

Safety Resources

- Airworthiness Matters: Next Generation Maintenance Human Factors Over the last 10-15 years, much attention has been focused on maintenance human factors training and reporting & investigating errors. While we could concentrate on simply doing more of these and certainly can find ways to do these things better, perhaps the next generation approach needs to include a much wider range of activities.

- Aircraft Maintenance: Going for Gold? Should we start treating maintenance personnel more like athletes who need to achieve peak performance every day?

- The Power of Safety Leadership

- Leadership and Trust

- Safety Performance Listening and Learning – AEROSPACE March 2017

- How To Develop Your Organisation’s Safety Culture

- James Reason’s 12 Principles of Error Management

- Back to the Future: Error Management

- Maintenance Human Factors: The Next Generation

- Critical Maintenance Tasks: EASA Part-M & -145 Change

- For Rotors Grease is the Word

- Maintenance Misdiagnosis Precursor to EC135T2 Tail Rotor Control Failure

- Misassembled Anti-Torque Pedals Cause EC135 Accident

- EC130B4 Accident: Incorrect TRDS Bearing Installation

- Fatal S-61N Dual Power Loss During Post Maintenance Check Flight

- AAIB Report on the Ditchings of EC225 G-REDW 10 May 2012 & G-CHCN 22 Oct 2012

- EC225 LN-OJF Accident Norway (29 April 2016) Investigation Timeline

- Super Puma Epicyclic Gear Health Monitoring Background

- AAR Bell 214ST Accident in Afghanistan in 2012: NTSB Report

- Fatal S-61N Dual Power Loss During Post Maintenance Check Flight

- Loss of AS332L1 LN-OPG off Brønnøysund, Norway, 8 September 1997

- Insecure Pitch Link Fatal R44 Accident

- EC135 Main Rotor Actuator Tie-Bar Failure

- Bell 429 TR Pitch Change Link Bearing Failure

- S-61N Damaged During Take Off When Swashplate Seized Due to Corrosion

- Tail Rotor Pitch Control Loss During Hoisting

- Sikorsky S-92A Loss of Tail Rotor Control Events

- NTSB Reveal Lax Maintenance Standards in Honolulu Tour Helicopter Accident

- Fukushima Police Leonardo AW139 Accident: JTSB Update

- Aerossurance Wins MAA HUMS Maintenance Credit Contract

- EASA HUMS Research Developments

- EASA & FAA HUMS / VHM Developments

- HeliOffshore Launch HUMS Best Practice Guide

- Helicopter HUMS Maintenance Credit: New Initiatives

- UPDATE 14 June 2020: Freewheel Jerk on an SA330J Puma at Sea: Oil Analysis Opportunity

- UPDATE 16 June 2020: CRJ-200 Landing Incident Highlighted US Maintenance Competency Inadequacies

- UPDATE 28 June 2020: Maintenance Issues in Fire-Fighting S-61A Accident

- UPDATE 5 September 2020: SAR AS365N3 Flying Control Disconnect: BFU Investigation

- UPDATE 7 August 2021: Prompt Emergency Landing Saves Powerline Survey Crew After MGB Pinion Failure

- UPDATE 9 July 2022: R44 Ditched After Loss of TGB & TR: Improper Maintenance

- UPDATE 29 July 2023: Missing Cotter Pin Causes Fatal S-61N Accident

- UPDATE 25 May 2025: CHC Sikorsky S-92A Seat Slide Surprise(s)

Maintenance Observation Programme (MOP)

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements:

Aerossurance can provide practice guidance and specialist support to successfully implement a MOP.

Aerossurance’s Andy Evans was recently interviewed about safety investigations, the perils of WYLFIWYF (What-You-Look-For-Is-What-You-Find) and some other ‘stuff’ by with Sam Lee of Integra Aerospace:

Recent Comments