Load Lost Due to Misrigged HESLO Under Slung Load Control Cable

On 27 April 2017, a Japanese Airbus Helicopters AS350B1, JA9743 of Nakanihon Air Service, lost an under slung crop spraying system while in flight at Toubetsu, Teshikaga Town, Kawakami-gun, Hokkaido. According to the Japan Transport Safety Board (JTSB) final report, released 31 May 2018, the Captain sat in the left seat and a pilot under training was in the right seat and pilot flying.

At around 11:58, as returning to the loading site in order to load the fertilizer to the empty spraying device, the rotorcraft accelerated from the speed at about 25 kt for spraying to the speed at about 60 kt, then turned to right at the altitude at about 50 m.

The under slung load was seen in the helicopter’s rearview mirror to fall away.

The HESLO Hardware

The JSTB explain that:

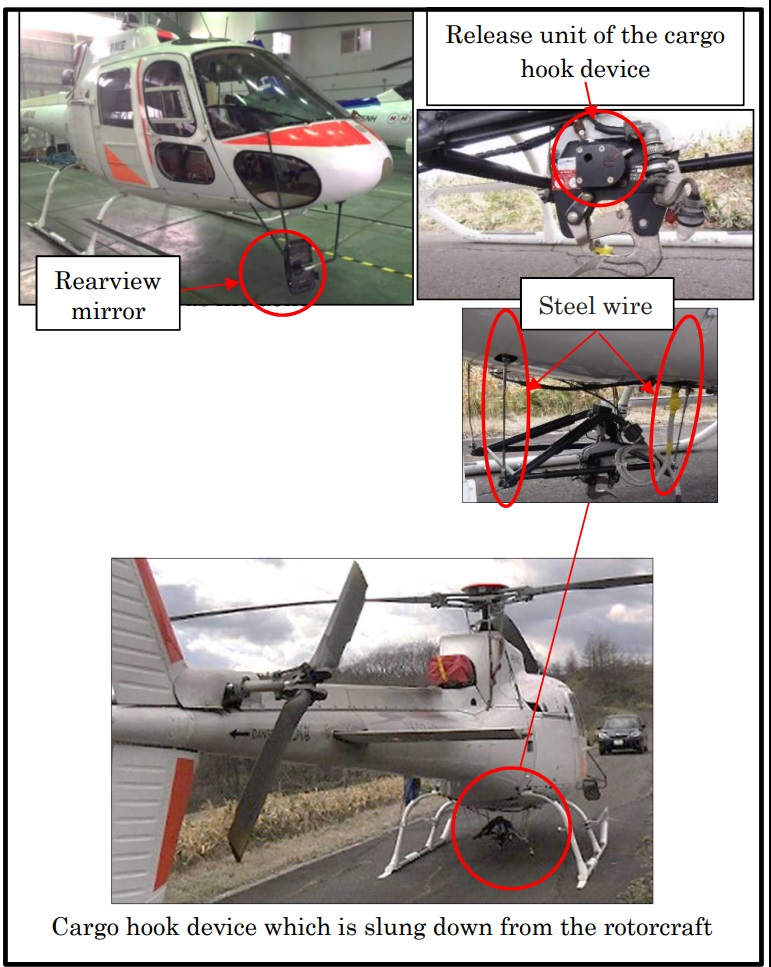

The Cargo Swing is hung from the bottom of the fuselage by four steel wires, utilizing the rotorcraft structure.

Configuration of Nakanihon Air Service Airbus Helicopters AS350B1 JA9743 Equipped for HESLO / USL External Load Operations (Credit: JTSB)

The Handle installed in the collective pitch lever is connecting to the [Control] Cable in order to actuate mechanically the Release Unit of the cargo hook device.

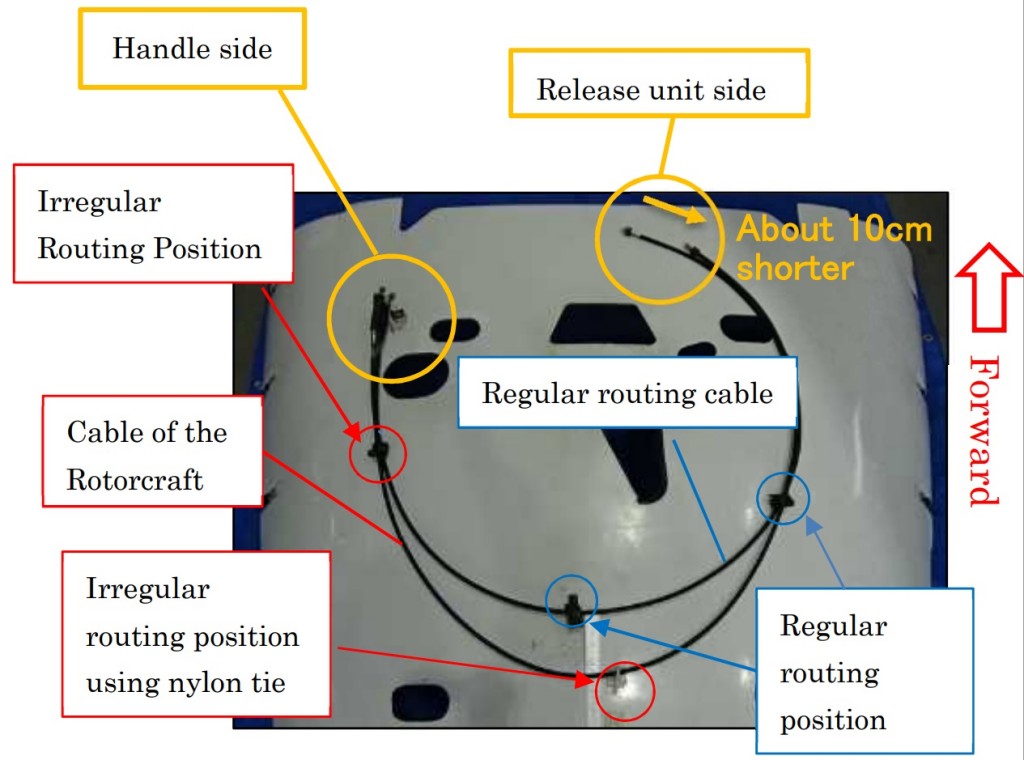

The Maintenance Manual requires the Control Cable is routed via clamps at two locations. On this aircraft the cable was fastened at three locations. One was a regular routing position but the other two were fastened at non-standard positions. One location used a nylon tie wrap used instead of a clamp.

AS350 External Load Control Cable with Regular Attachment Left and Tie Wraps Found on JA9743 Right (Credit: JSTB)

No maintenance records could be provided that showed when this alternative routing had been done. This would generate greater bigger friction, would have stopped the Control Cable smoothly following the movement of the Cargo Swing. This alternative routing also meant the cable was 10cm short at the Release Unit end, resulting in less cable and therefore free movement when attached to the Release Unit.

The Control Cable is a Bowden style cable, with a moving inner actuating cable. On detailed examination the outer protective cables of the Control Cable had broken, exposing the inner moving cable to damage. However an outer sheath would have prevented this being detected visually. It is possible that a large movement of the Cargo Swing, would have resulted in the shortened inner cable opening the Release Unit.

JSTB Conclusions

It is highly probable that the serious incident occurred because when the cargo swing was shaken due to the right turn following the acceleration of the rotorcraft to cause the outer cable of the cargo swing broke, the tension was applied to the inner cable, the release unit was activated to open the hook and the spraying device slung was dropped.

Regarding why the outer cable of the cargo swing broke and the tension was applied to the inner cable, it is highly probable that [this was because] the cable routing configuration was different from the regular routing configuration.

JTSB also comment:

Maintaining the regular configuration is important for the safe operation, and it is necessary to reconfirm the method to maintain the appropriate configuration management, like how to maintain the configuration or how to keep the records of the configuration changes

Safety Action

The operator changed all their cables following special training for maintenance personnel on this equipment. They have also reiterated the importance of configuration management to all staff.

No procedural, continuing airworthiness management or assurance changes are mentioned however.

Other Resources HESLO / USL

Also see our articles:

- What the HEC?! – Human External Cargo

- Helicopter Underslung Load: TV Transmitter

- French Skyscraper: Helicopter Underslung Load

- Keep Your Eyes on the Hook! Underslung External Load Safety

- EC120 Underslung Load Accident 26 September 2013 – Report

- Unexpected Load: AS350B3 USL / External Cargo Accident in Norway

- Unexpected Load: B407 USL / External Cargo Accident in PNG

- UPDATE 28 July 2018: Wayward Window: Fatal Loss of a Fire-Fighting Helicopter in NZ

- UPDATE 21 October 2018: Fallacy of ‘Training Out’ Error: Japanese AS332L1 Dropped Load

- UPDATE 1 December 2018: Helicopter Tail Rotor Strike from Firefighting Bucket

- UPDATE 20 December 2019: Helicopter External Sling Load Operation Occurrences in New Zealand

- UPDATE 28 June 2020: Maintenance Issues in Fire-Fighting S-61A Accident

- UPDATE 7 September 2020: Shocking Accident: Two Workers Electrocuted During HESLO

- UPDATE 31 October 2020: Loss of Control During HESLO Construction Task: BEA Highlight Wellbeing / Personal Readiness

- UPDATE 16 January 2021: NZ Firefighting AS350 Accident: Weaknesses in Role Equipment Design and Distribution of Key Operating Data

- UPDATE 2 April 2021: Windscreen Rain Refraction: Mountain Mine Site HESLO CFIT

- UPDATE 24 April 2021: Unballasted Sling Stings Speedy Squirrel (HESLO in France)

- UPDATE 12 June 2021: HESLO Dynamic Rollover in Alaska

- UPDATE 28 August 2021: Ditching after Blade Strike During HESLO from a Ship

- UPDATE 4 September 2021: Dynamic Rollover During HESLO at Gusty Mountain Site

- UPDATE 25 September 2021: Fuel Starvation During Powerline HESLO

- UPDATE 1 January 2022: Snagged Sling Line Pulled into Main Rotor During HESLO Shutdown

- UPDATE 18 March 2023: HESLO AS350 Fatal Accident Positioning with an Unloaded Long Line

- UPDATE 5 August 2023: A Concrete Case of Commercial Pressure: Fatal Swiss HESLO Accident

UPDATE 18 July 2019: UK AAIB report on a fatal accident to AS350B2 G-PLMH during HESLO with a boat at Loch Scadavay, Western Isles, Scotland, 13 June 2018.

Other Maintenance Standards and Practice Resources

- Airworthiness Matters: Next Generation Maintenance Human Factors Over the last 10-15 years, much attention has been focused on maintenance human factors training and reporting & investigating errors. While we could concentrate on simply doing more of these and certainly can find ways to do these things better, perhaps the next generation approach needs to include a much wider range of activities.

- Aircraft Maintenance: Going for Gold? Should we start treating maintenance personnel more like athletes who need to achieve peak performance every day?

- Safety Performance Listening and Learning – AEROSPACE March 2017

- How To Develop Your Organisation’s Safety Culture

- James Reason’s 12 Principles of Error Management

- Back to the Future: Error Management

- B747 Landing Gear Failure Due to Omission of Rig Pin During Maintenance

- When Down Is Up: 747 Actuator Installation Incident

- Hoist Assembly Errors: SAR Personnel Dropped Into Sea Taiwanese investigators determined that the hoist hook had been inappropriately assembled during maintenance 2 days earlier, raising questions on the technical knowledge of hoist maintenance.

- B1900D Emergency Landing: Maintenance Standards & Practices The TSB report posses many questions on the management and oversight of aircraft maintenance, competency and maintenance standards & practices. We look at opportunities for forward thinking MROs to improve their maintenance standards and practices.

- UPDATE 25 August 2018: Crossed Cables: Colgan Air B1900D N240CJ Maintenance Error On 26 August 2003 a B1900D crashed on take off after errors during flying control maintenance. We look at the maintenance human factor safety lessons from this and another B1900 accident that year.

See also UK CAA CAP 426 – Helicopter External Load Operations. CASA issued Airworthiness Bulletin 25-006 “to notify operators and maintainers of additional safety information and current design standards for cargo hooks installed in helicopters”. It discusses phenomena such as Dynamic Rollout (or Ring Reversal), Jammed Loads / Hooks, Uncommanded Release / Inadvertent Cargo Hook Opening etc.

FSF Maintenance Observation Program (MOP)

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements:

Recent Comments