Dornier 328-100 Crossed Apron During Runway Excursion (DANA 5N-DOX at Port Harcourt NAF Base)

On 23 January 2019 Dornier 328-100 turboprop 5N-DOX of DANA (Dornier Aviation Nigeria AIEP Limited) suffered a significant runway excursion at the Port Harcourt NAF Base, crossing the airport apron and stopping just 3 m from the boundary fence.

DANA Dornier 328-100 turboprop 5N-DOX Runway Excursion (Credit: AIB)

Nigeria’s Accident Investigation Bureau (AIB) released their safety investigation report on 30 December 2022. The aircraft was operating an oil and gas industry chartered flight from Bonny with 16 persons on board (2 Flight Crew, 1 Cabin Crew, 12 passengers, and 1 Aircraft Maintenance Engineer). The Co-Pilot (3,900 hours experience, 3,650 on type) was the Pilot Flying (PF) and the Aircraft Commander (18,400 hours, 6,500 on type) was the Pilot Monitoring (PM).

DANA Dornier 328-100 turboprop 5N-DOX (Credit: AIB)

On approach to PH NAF Base:

According to the crew at 6.2 NM they noticed that number 1 engine was producing torque higher than the recommended 20% for final approach and landing. At flight idle, it was indicating 24%, whereas the number 2 engine was indicating the normal 20% torque at flight idle.

At 10:00 h, [flight nember] DAV462 landed right of centreline runway 22. The crew also stated that, on idling the power lever during the landing roll, torque from number 1 engine increased to 27% instead of decrease below 10% causing a differential torque between the engines. It showed a maximum value of 34%. The torque from number 2 engine decreased below 10% (normal indication).

The aircraft veered off the runway to the right…and was uncontrollable despite rudder application. BETA light were sighted and speed was higher than normal taxi speed. Emergency park brake was engaged.

Specifically:

[T]he aircraft exited the runway at a distance of 1,190 m from the threshold of runway 22. It further travelled on the runway shoulder for a distance of about 105 m. At a distance of approximately 98 m of its movement on the runway shoulder, the No. 4 right main tyre broke a runway edge light.

DANA Dornier 328-100 turboprop 5N-DOX Runway Excursion. White arrow = tyre tracks, Red arrow = smashed runway light (Credit: AIB)

The aircraft further veered off the runway shoulder and continued on the grass verge. It covered a distance of about 262 m on the grass verge.

DANA Dornier 328-100 turboprop 5N-DOX Runway Excursion (Credit: AIB)

The aircraft travelled an additional distance of 259 m on the apron and came to a complete stop at about 3 m to the perimeter fence by the Aero Contractors ramp.

The aircraft was slightly damaged. The occupants were all uninjured. Luckily there were no aircraft or vehicles on the apron in the path of the Dornier.

The AIB Safety Investigation

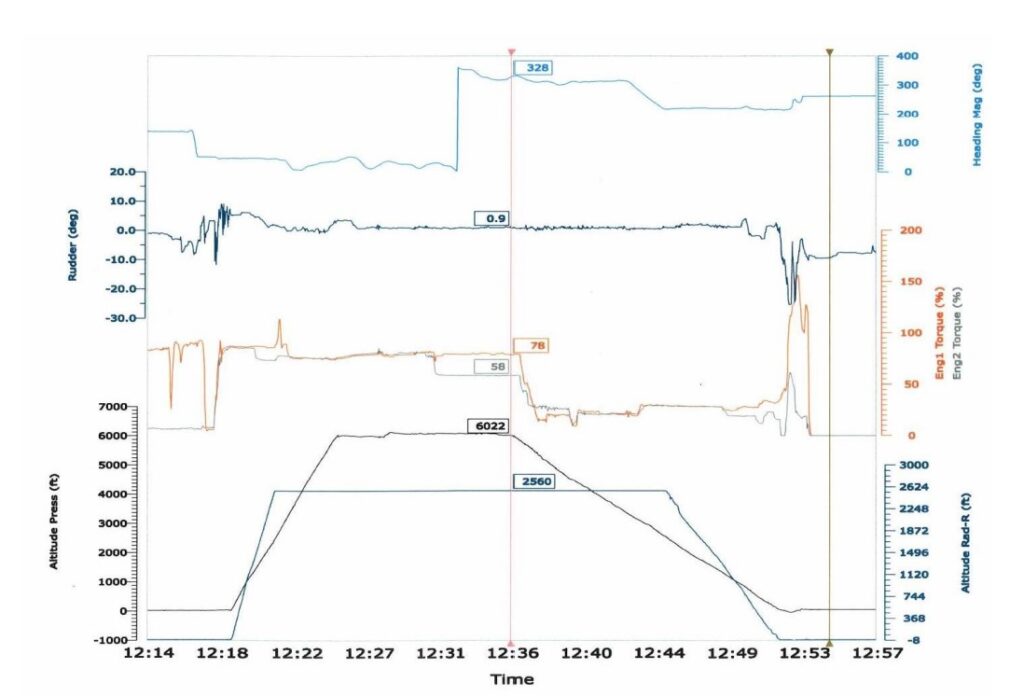

The AIB found the CVR data had been overwritten. The FDR showed a torque disparity of 20% (78/58) when at 6,000 ft 23 minutes prior to landing. There was an initial rudder displacement of 26° immediately after touchdown.

The disparity in the left and right propeller torque values is an indication of failure of the propeller control unit (PCU) of the number 1 engine.

Maintenance was conducted before investigators arrive:

The aircraft technical logbook entry of 23rd January 2019 (post-occurrence) indicated: “L/H engine propeller will not come out of feather. L/H PCU [model D-1192-2] replaced IAW DO328 MM 61-21-04. OPS, Rig Check, Leak Check, OK”.

Tyres were also replaced.

The PCU responds to commands from the pilot’s “power and condition levers and controls and actuates the propeller hydraulically using oil from the engine lubrication system”. The defective PCU was sent for tear down at the Hartzell Service Centre, at Piqua, Ohio:

The PCU failed the incoming ATP because of low pressure at the 400 pound relief valve. Pressure at the relief valve should be 470+/-30 psi. After disassembly, the filter was found to be full of a black silt-like substance. Visual inspection of the remaining part including the Coupling/Tube Assembly and Volume Exchange Unit exhibited signs of normal wear.

ANA Dornier 328-100 turboprop 5N-DOX Hartzell Propeller Control Unit (PCU)(Credit: AIB)

Disappointingly there is no further elaboration or analysis of the “black silt-like substance” in the AIB report or detail of the PCU history. AIB do however include 7 pages of cut and paste description on the PCU.

AIB state that:

The crew action to continue the approach under a normal landing checklist instead of the ABNOM-9-10 checklist was inappropriate.

Again, no further detail is included on that checklist.

The crew should have discontinued the approach and pick a hold over the station to execute the applicable checklist before coming in to land.

The investigation revealed certain lapses in crew adherence to checklist application and SOP compliance in this flight.

The tyre tracks showed that the aircraft landed right of the runway centerline and veered further right into the grass verge. This indicates the effect of a propeller torque asymmetry coupled with excessive rudder input…which the crew were unable to arrest.

AIB also state the emergency brake was applied late.

AIB Conclusions

Cause:

Asymmetrical propeller torque experienced on ground during landing roll due PCU failure in-flight.

Contributing Factors:

1. Non-recognition of the prevailing torque oscillation malfunction.

2. Non-execution of the proper checklist.

3. Excessive right rudder application after landing.

Safety Resources

You may also find these Aerossurance articles of interest:

- What Lies Beneath: The Scope of Safety Investigations

- B1900D Emergency Landing: Maintenance Standards & Practices

- How One Missing Washer Burnt Out a Boeing 737

- Fuel Tube Installation Trouble

- Fire After O-Ring Nipped on Installation

- Uncontained CFM56-7 Failures: Southwest B737-700s

- Uncontained PW1524G Failure During CS100 Certification Testing

- Machining Defect Cause of V2500 Failure

- B787 GEnx Fan Shaft Failure

- USAF Engine Shop in “Disarray” with a “Method of the Madness”: F-16CM Engine Fire

- Bell 407 Rolls-Royce 250-C47B Uncontained Engine Failure after Bearing Failure

- NTSB Confirms United Airlines Maintenance Error After 12 Years

- Machining Defect Cause of V2500 Failure

- ‘Aggressive’ Grit Blasting Maintenance Leads to Engine Fire & IFSD

- Micro FOD: Cessna 208B Grand Caravan Engine Failure & Forced Landing

- Cessna 208 Forced Landing: Engine Failure Due To Re-Assembly Error

- NDI Process Failures Preceded B777 PW4077 Engine FBO

- King Air 100 Uncontained TPE331-6 Failure – Inappropriate Repair Scheme

- B767 Fire and Uncommanded Evacuation After Lockwire Omitted

- Engine Life Limit Exceedance Caused Logging Helicopter Fatal Accident

- Engine Failure after Inadvertently Being Put Back into Service Incomplete

- Coking Causes Power Loss: Australian AS350BA

- Schiebel Camcopter S-100 Engine Failure Results in Baltic Crash

- Maintenance Misdiagnosis Precursor to Tail Rotor Control Failure

- Contaminated Oxygen on ‘Air Force One’

- B747 Landing Gear Failure Due to Omission of Rig Pin During Maintenance

- When Down Is Up: 747 Actuator Installation Incident

- Lost in Translation: Misrigged Main Landing Gear

- Maintenance Human Factors in Finnish F406 Landing Gear Collapse

- Hoist Assembly Errors: SAR Personnel Dropped Into Sea

- ERJ-190 Flying Control Rigging Error

- ATR 72 Rudder Travel Limitation Unit Incident: Latent Potential for Misassembly Meets Commercial Pressure

Aerossurance’s Andy Evans was recently interviewed about safety investigations, the perils of WYLFIWYF (What-You-Look-For-Is-What-You-Find) and some other ‘stuff’ by with Sam Lee of Integra Aerospace:

Recent Comments