Maintenance Distraction in Bell 407 Accident (N98ZA, Zip Aviation)

On 4 June 2022 Bell 407 N98ZA of New York air tour operator Zip Aviation crashed shortly after commencing a positioning flight to JFK International Airport, New York following maintenance at Caldwell Essex County Airport, New Jersey.

Wreckage of Zip Aviation Bell 407 N98ZA (Credit: Fairfield Fire Department)

The Accident Flight

According to the NTSB safety investigation report published on 20 September 2023, about 5 minutes after departure, at an altitude of about 500 ft amsl, the Appareo Vision 1000 onboard recording system captured the pilot (872 hours total time, 29 on type) saying, “what is going on here?”.

The pilot [when about 2 miles south of Teterboro Airport] subsequently contacted air traffic control and requested to return to the departure airport, but he did not declare an emergency or state that he needed assistance. Upon initial contact with the tower controller at the destination airport, the pilot stated that he “might need the runway”.

As the helicopter approached the airport and its indicated airspeed began to decay below about 30 knots, the helicopter entered a right yaw and completed several 360° rotations around the main rotor mast before impacting terrain next to the runway, resulting in substantial damage.

Wreckage of Zip Aviation Bell 407 N98ZA (Credit: FAA via NTSB)

The Safety Investigation

The Bell 407’s tail rotor was installed the day before after the replacement of four feathering bearings.

Examination by investigators revealed that the tail rotor crosshead drive plate, which was positioned behind the pitch change rod attachment nut, was not bolted to the tail rotor crosshead, as prescribed in the maintenance manual.

Zip Aviation Bell 407 N98ZA Tail Rotor Crosshead As Found (Credit: Bell via NTSB)

The two attachment bolts were not present, and no remnants of any bolts were found in their threaded receptacles in the crosshead drive plate

Exemplar Tail Rotor Crosshead Fully Assembled and Safety-Wired (Credit: Bell via NTSB)

The threads were undamaged and showed no signs of corrosion, deformation, smearing, or cross-threading.

During interview…

The director of maintenance (DOM), who performed the task, stated that he conducted the tail rotor assembly installation by laying out the parts on a maintenance cart; performing the installation procedure, including the mast nut torque application; and having a mechanic verify the mast nut torque. He then finished the installation and had another mechanic verify the work.

The mechanic who did the verification did hold a Inspection Authority and Zip Aviation did not “have an active RII [Required Inspection Item] program”. Despite promoting maintenance human factors (HF) for many years, there is still no FAA requirement to do independent inspections on this size of aircraft.

A company pilot performed a preflight inspection of the helicopter, ground functional checks, and three consecutive maintenance runs to balance the tail rotor.

The accident flight was the first flight after completion of this work.

Significantly:

According to the DOM, between the mast nut torque application and completion of the tail rotor assembly installation, he was “called out” to consult on two different aircraft repairs. The DOM did not recall the amount of time that elapsed before he resumed the installation work.

After the accident Zip Aviation developed an RII program.

NTSB Probable Cause

The failure of maintenance personnel to properly secure the tail rotor crosshead drive plate and the failure of maintenance personnel, the maintenance pilot, and the accident pilot to detect the error, which led to the helicopter’s loss of tail rotor antitorque.

Also causal was the pilot’s failure to maintain the helicopter’s airspeed at or above effective translational lift and perform a run-on landing, which resulted in a loss of control.

Wreckage of Zip Aviation Bell 407 N98ZA (Credit: Fairfield Police Department)

Safety Resources

The European Safety Promotion Network Rotorcraft (ESPN-R) has a helicopter safety discussion group on LinkedIn. You may also find these Aerossurance articles of interest:

- Fatal $16 Million Maintenance Errors

- Missing Cotter Pin Causes Fatal S-61N Accident

- Misrigged Flying Controls: Fatal Maintenance Check Flight Accident

- S-61N Accident in Afghanistan: Investigators Focus on Auxiliary Servocylinder

- Fatal S-61N Dual Power Loss During Post Maintenance Check Flight

- S-61N Damaged During Take Off When Swashplate Seized Due to Corrosion

- Main Rotor Blade Certification Anomaly in Fatal Canadian Accident

- Canadian B212 Crash: A Defective Production Process

- AAIB Report on the Ditchings of EC225 G-REDW 10 May 2012 & G-CHCN 22 Oct 2012

- EC225 LN-OJF Norway Accident Investigation Timeline

- In-Flight Flying Control Failure: Indonesian Sikorsky S-76C+ PK-FUP

- AAR Bell 214ST Accident in Afghanistan in 2012: NTSB Report

- Airworthiness Directive after Two Fatal Bell 430 Accidents: Main Rotor – Pitch Link Clevis Fractures Angola and South Africa

- Ungreased Japanese AS332L Tail Rotor Fatally Failed

- EC120 Forgotten Walkaround

- Managing Interruptions: HEMS Call-Out During Engine Rinse

- Maintenance Misdiagnosis Precursor to EC135T2 Tail Rotor Control Failure

- Misassembled Anti-Torque Pedals Cause EC135 Accident

- EC130B4 Accident: Incorrect TRDS Bearing Installation

- Loose B-Nut: Accident During Helicopter Maintenance Check Flight

- BEA Point to Inadequate Maintenance Data and Possible Non-Conforming Fasteners in ATR 42 Door Loss

- BA A319 Double Cowling Loss and Fire – AAIB Report

- BA A319 Double Cowling Loss and Fire – AAIB Safety Recommendation Update

- ANSV Report on EasyJet A320 Fan Cowl Door Loss: Maintenance Human Factors

- Tiger A320 Fan Cowl Door Loss & Human Factors: Singapore TSIB Report

- Human Factors of Dash 8 Panel Loss

- EC135 Air Ambulance CFIT when Pilot Distracted Correcting Tech Log Errors

- Fire-Fighting AS350 Hydraulics Accident: Dormant Miswiring

- ATR 72 Rudder Travel Limitation Unit Incident: Latent Potential for Misassembly Meets Commercial Pressure

- Fuel Tube Installation Trouble

- How One Missing Washer Burnt Out a Boeing 737

- B1900D Emergency Landing: Maintenance Standards & Practices

- The Loss of RAF F-35B ZM152: An Organisational Accident

- A Concrete Case of Commercial Pressure: Fatal Swiss HESLO Accident

You might find these safety / human factors resources of interest:

- James Reason’s 12 Principles of Error Management

- Back to the Future: Error Management

- This 2006 review of the book Resilience Engineering by Hollnagel, Woods and Leveson, presented to the RAeS by Aerossurance’s Andy Evans: Resilience Engineering – A Review and this book review of Dekker’s The Field Guide to Understanding Human Error: The Field Guide to Understanding Human Error – A Review

- What Lies Beneath: The Scope of Safety Investigations

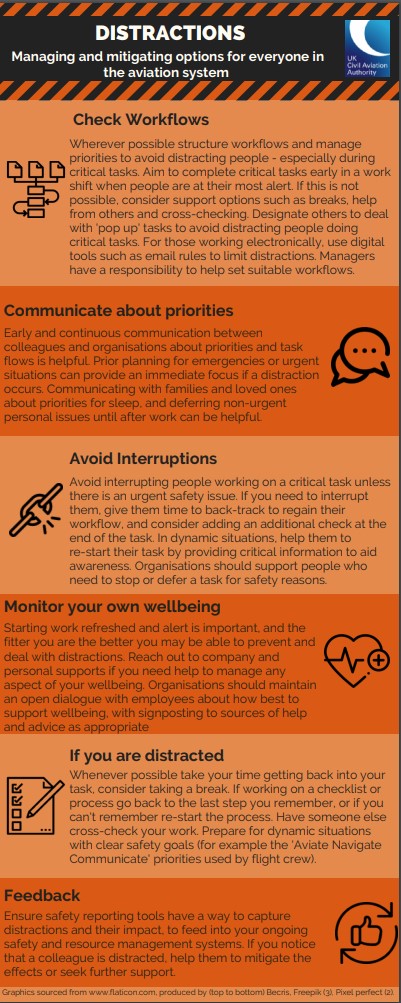

The UK CAA has issued this infographic on distraction:

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements:

Recent Comments