Attention on Engine Shop Assembly of a S-92A GE CT7-8 after North Sea IFSD (Bristow Norway LN-OMI)

On 5 June 2023, Sikorsky S-92A LN-OMI of Bristow Norway, suffered an uncommanded in flight shut down of one GE CT7-8 engine shortly after take off from the Linus jack up rig, 10 NM west of Ekofisk Lima in the Norwegian sector of the North Sea. The helicopter continued on to make a safe landing at Stavanger Airport.

On 26 November 2025 the Norwegian Safety Investigation Authority (NSIA) issued their safety investigation report that focused on events during the previous engine ovehaul shop visit in Spain.

The Incident Flight

NSIA explain that after take off from the Linus and climbing to between 3,000 and 4,000 feet…

…the crew heard a loud bang, simultaneously as the helicopter’s instruments indicated that the left engine had stopped. The…pilots went through the relevant checklists. They contacted air traffic control and issued a mayday call. After a brief round of troubleshooting, it was determined that the engine could not be restarted, and the flight would have to continue on one engine.

The pilots chose to fly directly to Stavanger Airport Sola after evaluating that the helicopters performance was not sufficient to perform an emergency landing on the platform offshore.

Along the way, the helicopter was met by a helicopter from the rescue service.

The helicopter landed safely onshore.

The Safety Investigation: Engine Examination

The NSIA has carried out a brief review of the operational incident and conducted interviews with both pilots. The interviews reveals that the crew was following the company’s procedures.

On initial engine inspection no visual damage to the left engine was found apart from “small pieces of metal found in the turbine area”. It was also found that the compressor was not rotating with its turbine.

The left engine was sent for strip independently at a UK maintenance facility.

The CT7-8 has a 5 stage axial and single stage centrifugal compressor. This is connected by an rear shaft to the gas generator turbine. At the UK facility…

The engine’s cold section, hot section and turbine were dismantled. When dismantling the cold section, it was found that the joint between the centrifugal impeller and the compressor rotor rear shaft had disconnected.

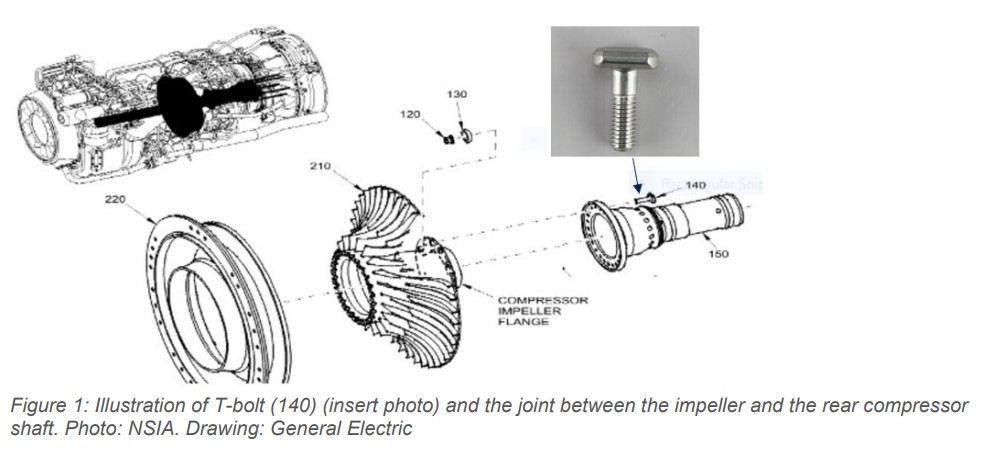

The impeller and rear compressor shaft have an interference fit and are normally joined by twelve T-head rotor bolts.

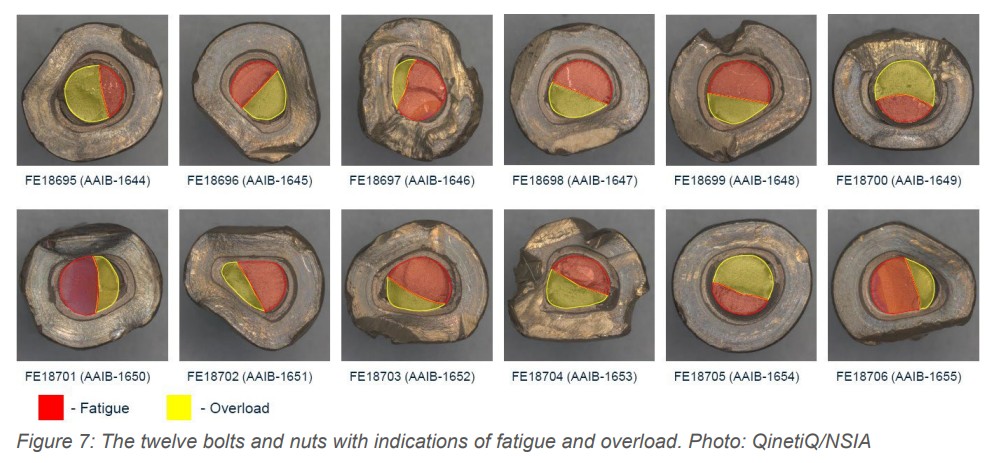

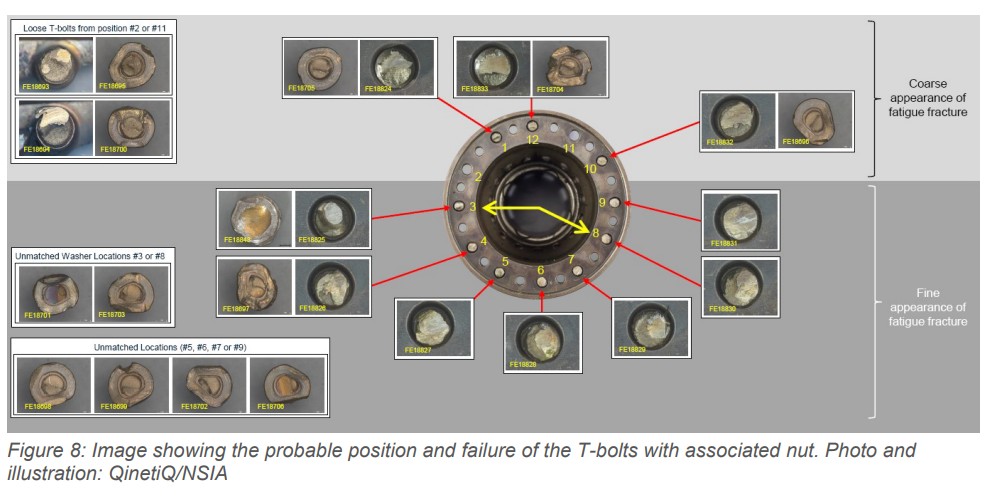

Laboratory examination found evidence of fatigue in all 12 Inconel 718 T-bolts.

Fatigue fractures had initiated at multiple locations on the individual T-bolts, with the fatigue cracks merging into a dominant crack as the fatigue propagated.

All the bolts fractured, causing the rear shaft to detach from the centrifugal impeller…

…and the in flight shut down.

The Safety Investigation: Maintenance History

NSIA report that the had been removed from another helicopter on 30 May 2020 and sent to the ITP overhaul facility in Albacete. At that time:

The compressor had rubbed against the compressor casing, and the oil pressure was reported to be too high. No other significant abnormalities was reported.

In 2021, the engine was test-run after repair but was rejected since the oil pressure remained too high. This was rectified.

While the fault was being rectified, the engine’s original fuel control was removed (cannibalised) to be used on another engine. Another used, removed serviceable fuel control was fitted, and the engine was prepared for another test run.

However:

During the test run, the engine suffered a flameout and stopped abruptly. ITP subsequently concluded that the cause was a fault in the newly installed engine’s fuel control.

The engine suffered extensive damage as a result of the incident and had to be returned [from test] to the shop for repair.

NSIA note that:

ITP Work Order 42355 contain 920 pages and describes the work that was carried out. The NSIA…reviewed the parts of the work order that deal with the installation, assembly and

balancing of the compressor rotor. The work order showed, among other things, that twelve new T-bolts had been used during assembly.

The flanges were measured and recorded. NSIA identified a confusion between how tolerances were expressed in the workshop manual and the Work Order which resulted in the flange being out of tolerance at the nine o’clock and twelve o’clock positions. However, the investigators concluded his was irrelevant to the incident.

ITP’s misinterpretation of the manual has been reported to General Electric, who will update the shop manual…

The engine passed the next test. An EASA Form 1 was issued on 22 June 2022. The engine was installed in LN-OMI 16 November 2022. At that time, the engine had accumulated 11,015 engine hours. At the time of the incident it has run 11,909 engine hours

To learn more about how the work was carried out in practice, the NSIA visited ITP’s workshop in Albacete, Spain…

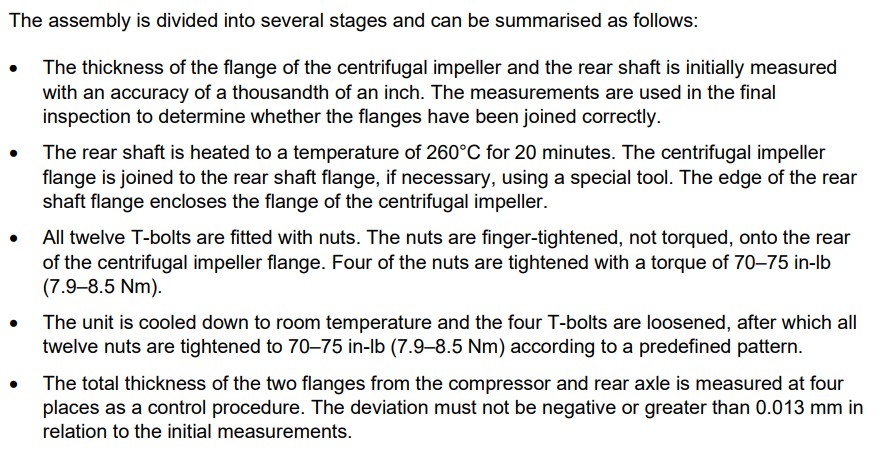

A run-through of the procedure with a technician on the CT7-8 demonstrated the various stages, including that the joining must be carried out without interruption due to the heating and cooling processes.

The technician also demonstrated how the compressor rotor was balanced afterwards.

At the time of the engine repair ITP carried out an annual calibration check on torque wrenches but didn’t test them before use.

The maintenance records did not record which torque wrench was used, however, ITP’s tooling computer tracking system indicated a Facom R.306U, serial number F03 7226, had been used. This torque wrench has a defined range of 50 to 250 in-lb.

Facom has specified in the user manual R.306U_0607-D that the torque wrench should be

checked regularly or at least once a year or more often in case of frequent use. The official ISO standard, 6789, sets requirements for annual calibration or when it has been used 5,000 times.

It was calibrated as follows:

- September 2021: maximum deviation was –3.40% at 50 in-lb

- October 2022: maximum deviation was +3.18% at 50 in-lb.

NSIA Conclusions

While NSIA conducted a series of examinations of the engine they were unable to determine the root cause of the T-bolts’ failure.

NSIA finds it unlikely that the incident occurred because of a material defect in the T-bolts.

However, potentially:

It may be that the tightening torque when installing the T-bolts has not been within the specified values on one or more T-bolts. It may have started at the location where the balance weights were installed with too low or too high a torque. It may also be that the joint of the two components has inadvertently not been matched correctly when installed.

NSIA note that:

The assembly of the centrifugal compressor and the rear shaft is a critical and complex task with several different work steps, including the dismantling of T-bolts to install balance weights. The complexity of the task increases the risk of human error.

The NSIA believes that the engine Shop Manual GEK 105175 can be improved to reduce the risk of human error with more clear wording between the worksteps and figures. In addition could an additional work step be established in the Shop Manual where the twelve T-bolts nuts are rechecked for correct tightening torque in the final inspection after the installation of the balance weights.

The Norwegian Safety Investigation Authority recommends that General Electric update the Shop Manual GEK 105175 to include a safety measurement to identify possible human errors after the assembly and balancing of the compressor safety rotor has been completed.

NSIA observe that:

The entire work procedure with the joining of the centrifugal impeller and the rear shaft was signed by one technician. The joining is to NSIA’s judgement a critical task where requirements are set for a procedure to identify errors or defects (error capturing) [as per Part-145.A.48(c)].

NSIA also believed in was necessary…

…to consider whether the test regime for the wrench should be intensified as the deviation on the torque wrench in question was negative (-3.4%) one year and positive the following year (+3.18%).

Safety Action

ITP conducted its own internal investigation implemented following measure:

The measures are consistent with the NSIA’s analysis. NSIA therefore does not make any safety recommendations to ITP.

NSIA also believes that the change shows that the company has a process of continuous improvement to correct its operations after a serious incident.

Safety Resources

The European Safety Promotion Network Rotorcraft (ESPN-R) has a helicopter safety discussion group on LinkedIn. You may also find these Aerossurance articles of interest:

- B1900D Emergency Landing: Maintenance Standards & Practices The TSB report posses many questions on the management and oversight of aircraft maintenance, competency and maintenance standards & practices. We look at opportunities for forward thinking MROs to improve their maintenance standards and practices.

- BA B747 Landing Gear Failure Due to Omission of Rig Pin During Maintenance

- What a Difference a Hole Makes: E-8C JSTARS $7.35 million Radar Mishap

- USAF Tool Trouble: “Near Catastrophic” $25mn E-8C FOD Fuel Tank Rupture

- Inadequate Maintenance, An Engine Failure and Mishandling: Crash of a USAF WC-130H

- USAF Engine Shop in “Disarray” with a “Method of the Madness”: F-16CM Engine Fire

- Inadequate Maintenance at a USAF Depot Featured in Fatal USMC KC-130T Accident

- When Down Is Up: 747 Actuator Installation Incident

- Maintenance Human Factors in Finnish F406 Landing Gear Collapse

- Lost in Translation: Misrigged Main Landing Gear

- Cessna Citation Excel Controls Freeze

- B214ST Tail Rotor Drive Shaft Coupling Misassembly

- Crossed Cables: Colgan Air B1900D N240CJ Maintenance Error

- Crazy KC-10 Boom Loss: Informal Maintenance Shift Handovers and Skipped Tasks

- Frozen Dash 8-100 Landing Gear After ‘Improper Maintenance Practices’ Say NTSB

- ATR 72 Rudder Travel Limitation Unit Incident: Latent Potential for Misassembly Meets Commercial Pressure

- Loose B-Nut: Accident During Helicopter Maintenance Check Flight

- USAF RC-135V Rivet Joint Oxygen Fire

- CHC Sikorsky S-92A Seat Slide Surprise(s)

- SAR AS365N3 Flying Control Disconnect: BFU Investigation

- In-Flight Flying Control Failure: Indonesian Sikorsky S-76C+ PK-FUP

- AAR Bell 214ST Accident in Afghanistan in 2012: NTSB Report

- Misassembled Anti-Torque Pedals Cause EC135 Accident

- EC130B4 Accident: Incorrect TRDS Bearing Installation

- Ungreased Japanese AS332L Tail Rotor Fatally Failed

- R44 Ditched After Loss of TGB & TR: Improper Maintenance

- Missing Cotter Pin Causes Fatal S-61N Accident

- Emergency S-76D Landing Due to Fumes

- Engine & Emergency Flotation Failures – Greenland B206L4 Ditching

- The Missing Igniters: Fatigue & Management of Change Shortcomings

- FAA Rules Applied: So Misrigged Flying Controls Undetected

- BEA Point to Inadequate Maintenance Data and Possible Non-Conforming Fasteners in ATR 42 Door Loss

- BA A319 Double Cowling Loss and Fire – AAIB Report

- BA A319 Double Cowling Loss and Fire – AAIB Safety Recommendation Update

- ANSV Report on EasyJet A320 Fan Cowl Door Loss: Maintenance Human Factors

- Tiger A320 Fan Cowl Door Loss & Human Factors: Singapore TSIB Report

- Human Factors of Dash 8 Panel Loss

- Fuel Tube Installation Trouble

- How One Missing Washer Burnt Out a Boeing 737

- Flying Control FOD: Screwdriver Found in C208 Controls

- Cessna 208 Forced Landing: Engine Failure Due To Re-Assembly Error

- Meeting Your Waterloo: Competence Assessment and Remembering the Lessons of Past Accidents

- Cold Comfort Conference Call: USAF F-35A Alaska Accident

- The Loss of RAF F-35B ZM152: An Organisational Accident A £81 mn fighter is downed by FOD, one of its own intake blanks. This case study illustrates James Reason’s concept of Organisational Accidents and how just asking “who left the intake blank ?” misses the real reasons behind this accident.

You might find these safety / human factors resources of interest:

- James Reason’s 12 Principles of Error Management

- Back to the Future: Error Management

- This 2006 review of the book Resilience Engineering by Hollnagel, Woods and Leveson, presented to the RAeS by Aerossurance’s Andy Evans: Resilience Engineering – A Review and this book review of Dekker’s The Field Guide to Understanding Human Error: The Field Guide to Understanding Human Error – A Review

- Airworthiness Matters: Next Generation Maintenance Human Factors

FSF Maintenance Observation Programme (MOP)

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements:

Aerossurance can provide practice guidance and specialist support to successfully implement a MOP.

Recent Comments