Compressive Creep and the Loss of a Bell UH-1H’s Tail Rotor (N3276T, Mesa, AZ)

On 24 April 2020 Bell UH-1H N3276T of VNC LLC / Southwest Rotors was destroyed in an accident at Mesa, Arizona. One pilot died and the other miraculously survived but was seriously injured.

The helicopter was positioning from Jacqueline Cochran Regional Airport (TRM), Palm Springs, California to Falcon Field Airport (FFZ), Mesa. The helicopter was type certificated in the restricted category under the Federal Aviation Administration (FAA) Type Certificate Data Sheet (TCDS) H7SO, held by Overseas Aircraft Support Inc since 2008.

In their safety investigation report, published 3 May 2022, the US National Transportation Safety Board (NTSB) say witnesses reported…

…they observed…white smoke emitting from the tail rotor area.

Suddenly, the tail rotor separated from the helicopter… [which] started to spin and impacted the ground.

The debris trial was 1/2 mile long. The tail rotor assembly was found at one end and the fuselage, along with most of the debris, at the other end.

The NTSB Safety Investigation

The NTSB report that:

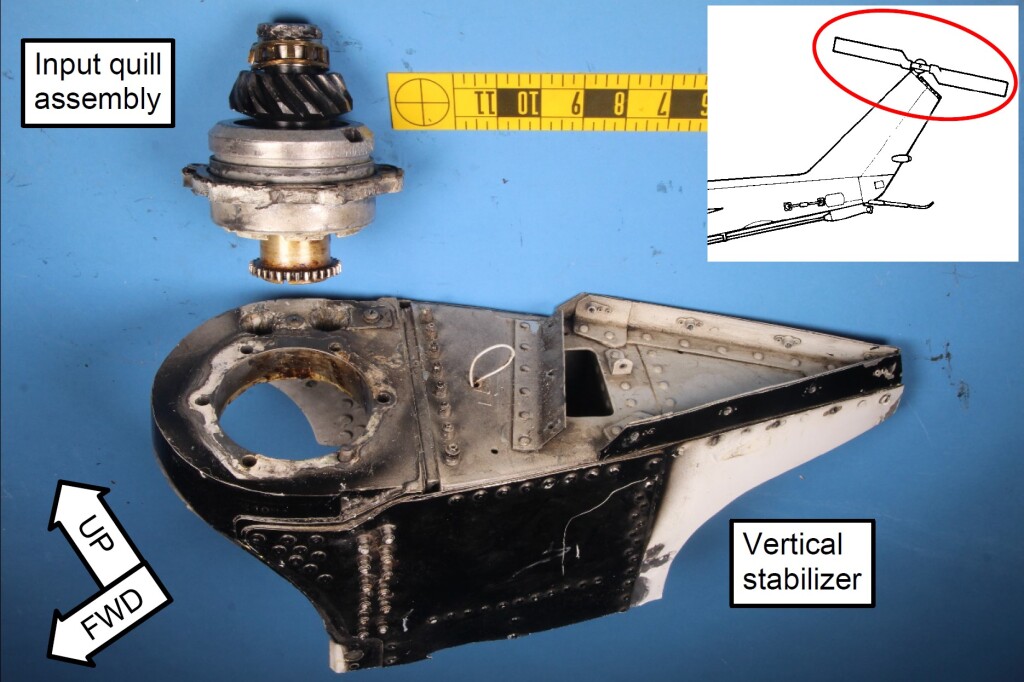

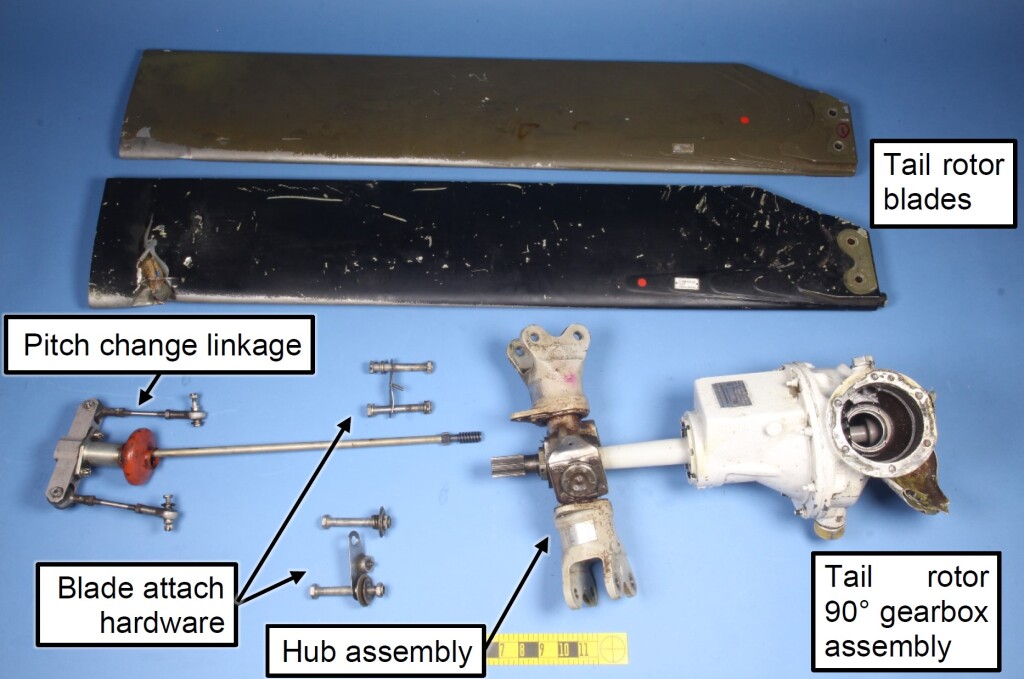

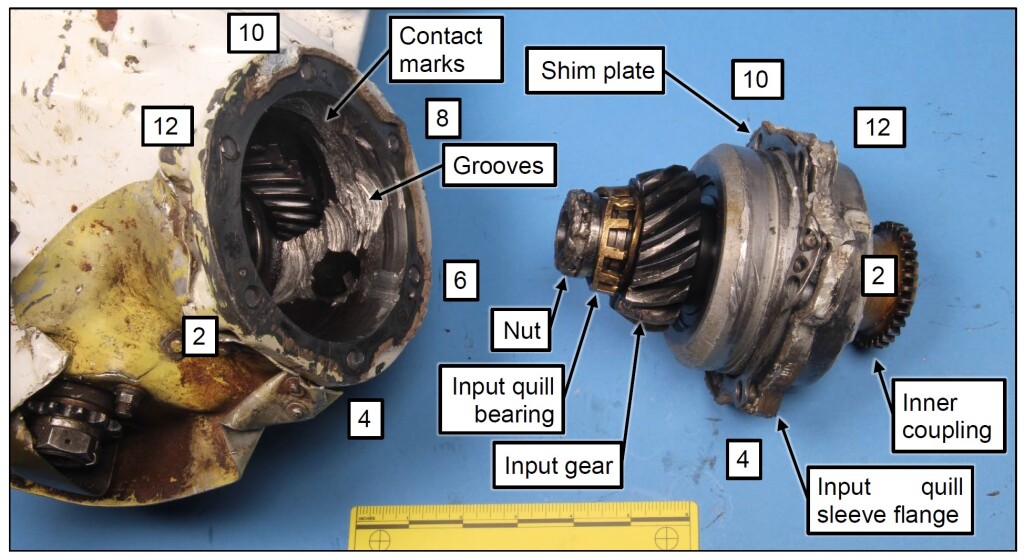

The tail rotor gearbox was fracture-separated at the attachment studs, and four of the fractured attachment stud pieces were found loose within the vertical stabilizer.

A fifth stud piece remained stuck in the vertical stabilizer support casting, and the nut end of the sixth stud piece was not located. The chip detector was removed from the tail rotor gearbox and metallic debris was present.

The tail rotor assembly was mostly whole and intact. The linkages and tail rotor blades remained secured in place.

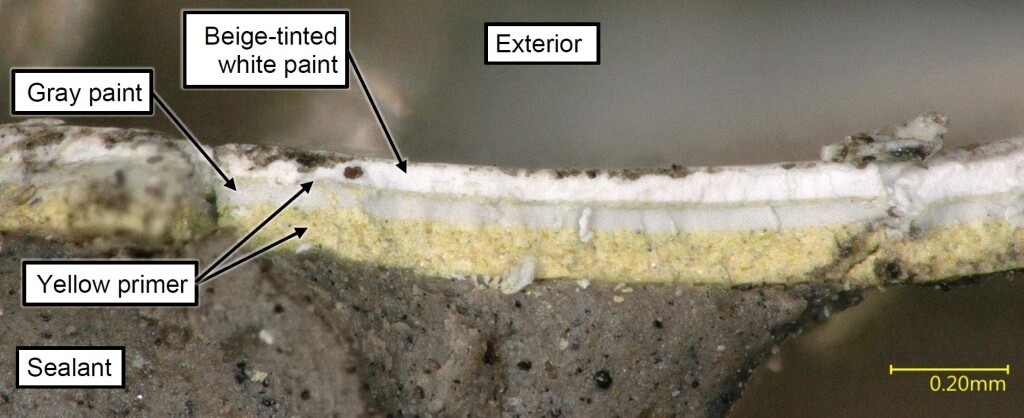

Progressive crack growth was noted on the mounting studs within the tail rotor gearbox housing. The fracture surfaces were relatively rough, consistent with low cycle fatigue or cyclic overstress crack growth under relatively high cyclic stresses. Additionally, multiple layers of primer, paint, and sealant were observed on the input quill assembly, including paint on the flange clamping surface where it had mated to the vertical stabilizer. Paint was also observed on the vertical stabilizer support casting where it had mated to the input quill as well as the washers for the tail rotor gearbox attachment hardware.

The US Army Depot Maintenance Work Requirement No. 55-1560-127 contains instructions for painting the tail rotor gearbox. The instructions contain a step to “mask the top part of the outer flange of input quill sleeve and also the entire studs.”

In 2012, the gearbox was removed from another helicopter, repaired, painted, and installed on the accident helicopter.

According to the NTSB, the TGB had a main input seal replaced before the painting at Heliponents Inc in Mesa.

The FAA requested the detailed work order from the repair station, but those records were no longer available.

Then in January 2019…

…the helicopter was painted and photographs that were taken during this process indicated that the tail boom, tail rotor gearbox, and tail rotor assembly remained installed during the painting process. In addition, the tail rotor assembly and tail rotor gearbox were masked.

Therefore, the paint found on the contact mounting surfaces was likely applied during the gearbox installation in 2012.

Th NTSB go on to explain that 39 flying hours earlier…

…in April 2019, the tail rotor gearbox was removed from the vertical stabilizer for a corrosion inspection; no defects were noted in the maintenance logs. A retorque and/or torque stabilization check was not completed after the gearbox was installed, nor was it required to be according to applicable technical manuals.

A re-torque was included in the Maintenance Manual for the Bell 205, the original new built civil certified equivalent, between 10 and 25 hours after installation.

In their analysis the NTSB state that paint on the contact surface been the TGB and vertical stabiliser “can lead to excessive relaxation of clamping forces due to compressive creep deformation of the paint” and “was likely a factor in the eventual reduction in clamping force” after being disturbed in April 2019 .

The reduction in clamping force on the installation led to the initiation of fatigue fractures on the attachment studs and subsequent separation of the tail rotor gearbox from the vertical stabilizer in flight. The separation of the tail rotor gearbox resulted in a loss of directional control of the helicopter. Had a retorque and/or torque stabilization check of the gearbox retaining nuts been required, it could have identified the reduction in clamping force of the tail rotor gearbox’s installation onto the vertical stabilizer prior to the accident.

Although the NTSB do not comment on this, a possible health monitoring warning sign also did not trigger an intervention:

An oil analysis report…reported abnormal copper and aluminum wear particle levels within the TRGB [sic] oil. The report noted that the oil sample date was December 17, 2019, about 6.8 flight hours prior to the accident. The oil analysis determined the wear levels for copper and aluminum were at 14 parts per million (ppm) and 12 ppm, respectively. The abnormal threshold was 8 ppm for both copper and aluminum. The oil analysis recommended no corrective action at that time, but to resample at the next service interval…25 flight hours.

The abnormal levels of metal contamination were undoubtedly due to the movement of the TGB after the loss of clamping load.

NTSB Probable Cause

An in-flight separation of the tail rotor gearbox from the airframe due to fatigue failure of the gearbox attachment studs, resulting in a loss of directional control and subsequent ground impact.

Contributing to the accident were 1) the improper application of paint on the clamping surfaces between the tail rotor gearbox and the vertical stabilizer that led to the initiation of fatigue fractures on the gearbox attachment studs and 2) the lack of a requirement to check the torque of the gearbox attachment hardware after installation of a gearbox onto the airframe.

No safety recommendations were raised by NTSB.

Safety Resources

The European Safety Promotion Network Rotorcraft (ESPN-R) has a helicopter safety discussion group on LinkedIn. You may also find these Aerossurance articles of interest:

- Airworthiness Matters: Next Generation Maintenance Human Factors

- Aircraft Maintenance: Going for Gold?

- B1900D Emergency Landing: Maintenance Standards & Practices

- Poor Painting Prevents Proper Performance: Shorts Sherpa NLG Collapse

- Freewheel Jerk on an SA330J Puma at Sea: Oil Analysis Opportunity

- Maintenance Issues in Fire-Fighting S-61A Accident

- Wasp Stung By Lack of Lubrication

- Yuma Hawk Accident: Lessons on Ex-Military Aircraft Operation

- Usage Related Ex-Military Helicopter Accident (UH-1H, N175SF)

- UH-1H HESLO Fuel Exhaustion Accident

- OH-58C Crash After MRB Fatigue Crack

- Engine Life Limit Exceedance Caused Logging Helicopter Fatal Accident

- Engine Failure after Inadvertently Being Put Back into Service Incomplete

- Coking Causes Power Loss: Australian AS350BA

- Prior Engine Mount Damage Lead to Fatal Aerial Saw Crash

- RCMP AS350B3 Left Uncovered During Snowfall Fatally Loses Power on Take Off

- Loose Engine B-Nut Triggers Fatal Forced Landing

- Fatal Engine Power Loss: Powerline Helicopter Not Modified IAW OEM Recommendations

- Forced Landing after CAMO Underestimated Operation in Dusty Environments

- Prompt Emergency Landing Saves Powerline Survey Crew After MGB Pinion Failure

- Bell 407 Rolls-Royce 250-C47B Uncontained Engine Failure after Bearing Failure

- B747 Landing Gear Failure Due to Omission of Rig Pin During Maintenance

- When Down Is Up: 747 Actuator Installation Incident

- Lost in Translation: Misrigged Main Landing Gear

- Maintenance Human Factors in Finnish F406 Landing Gear Collapse

- Inadequate Maintenance, An Engine Failure and Mishandling: Crash of a USAF WC-130H

- USAF Engine Shop in “Disarray” with a “Method of the Madness”: F-16CM Engine Fire

- Inadequate Maintenance at a USAF Depot Featured in Fatal USMC KC-130T Accident

- ATR72 VH-FVR Missed Damage: Maintenance Lessons

- Crazy’ KC-10 Boom Loss: Informal Maintenance Shift Handovers and Skipped Tasks

- Dash 8 Q400 Return to Base After Pitot System Contaminated By Unapproved Test Kit Lubricant

- Luftwaffe VVIP Global 5000 Written Off After Flying Control Assembly Error

- NTSB Confirms United Airlines Maintenance Error After 12 Years

- Poor Painting Prevents Proper Performance: Shorts Sherpa NLG Collapse

- Ungreased Japanese AS332L Tail Rotor Fatally Failed

- B767 Fire and Uncommanded Evacuation After Lockwire Omitted

- CRJ-200 Landing Incident Highlighted US Maintenance Competency Inadequacies

- Frozen Dash 8-100 Landing Gear After ‘Improper Maintenance Practices’ Say NTSB

- Fire-Fighting AS350 Hydraulics Accident: Dormant Miswiring

- ATR 72 Rudder Travel Limitation Unit Incident: Latent Potential for Misassembly Meets Commercial Pressure

- For Rotors Grease is the Word

- Maintenance Misdiagnosis Precursor to EC135T2 Tail Rotor Control Failure

- Misassembled Anti-Torque Pedals Cause EC135 Accident

- EC130B4 Accident: Incorrect TRDS Bearing Installation

- Fatal S-61N Dual Power Loss During Post Maintenance Check Flight

- AAIB Report on the Ditchings of EC225 G-REDW 10 May 2012 & G-CHCN 22 Oct 2012

- EC225 LN-OJF Accident Norway (29 April 2016) Investigation Timeline

- AAR Bell 214ST Accident in Afghanistan in 2012: NTSB Report

- Fatal S-61N Dual Power Loss During Post Maintenance Check Flight

- Loss of AS332L1 LN-OPG off Brønnøysund, Norway, 8 September 1997

- Insecure Pitch Link Fatal R44 Accident

- EC135 Main Rotor Actuator Tie-Bar Failure

- Bell 429 TR Pitch Change Link Bearing Failure

- S-61N Damaged During Take Off When Swashplate Seized Due to Corrosion

- Tail Rotor Pitch Control Loss During Hoisting

- Sikorsky S-92A Loss of Tail Rotor Control Events

- NTSB Reveal Lax Maintenance Standards in Honolulu Tour Helicopter Accident

- UPDATE 9 July 2022: R44 Ditched After Loss of TGB & TR: Improper Maintenance

- UPDATE 30 July 2022: B212 LOC-I: Windshear Encounter in the Lee of Mountain Ridge

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements.

Aerossurance’s Andy Evans was recently interviewed about safety investigations, the perils of WYLFIWYF (What-You-Look-For-Is-What-You-Find) and some other ‘stuff’ by with Sam Lee of Integra Aerospace:

Recent Comments